The space race between countries has intensified from exploration and mining of the moon and asteroids, launching large LEO constellations for providing global connectivity monitoring earth to NASA’s $10 billion James Webb Space Telescope.

Over the past three years, SpaceX has deployed thousands of satellites into low-Earth orbit as part of its business to beam high-speed internet service from space. But the company’s latest deployment of 49 new satellites after a Feb. 2021 launch did not go as planned.

As a consequence of a geomagnetic storm triggered by a recent outburst of the sun, up to 40 of 49 newly launched Starlink satellites have been knocked out of commission. They are in the process of re-entering Earth’s atmosphere, where they will be incinerated.

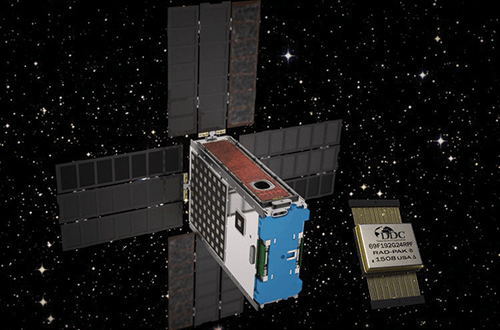

Future small satellite systems for both Earth observation as well as deep-space exploration are greatly enabled by the technological advances in deep sub-micron microelectronics technologies. Ensuring the reliable operation of microcircuits in outer space is an important scientific and economic objective. For modern weather, communications and surveillance satellites to be cost-effective, they need to be operational for at least 10 to 15 years.

But with extended space missions comes the requirement for flawless performance by on-board equipment over a period of years, in a very harsh environment. On takeoff, electronic components endure violent beatings from extreme vibration, and once in orbit, every material needs to be able to endure wildly shifting thermal changes that can see a cycle through 260 degrees Fahrenheit (126.67 degrees Celsius) every hour of every day.

Deep-space and long-duration missions, where both crew members and spacecraft no longer benefit from the protection of Earth’s magnetic fields, are considered high risk for adverse radiation impacts. Aircraft flying at altitude, at about 30,000 feet and above, also are starting to experience radiation-induced effects. “There are 500 times more neutrons at 30,000 feet than there are on the ground,” points out Aitech’s Romaniuk. Long term exposure of astronauts to radiation is problematic and the effect that space radiation has on spacecraft electronics and software is equally challenging.

Future small satellite systems for both Earth observation as well as deep-space exploration are greatly enabled by the technological advances in deep sub-micron microelectronics technologies. For modern weather, communications and surveillance satellites to be cost-effective, they need to be operational for at least 10 to 15 years. Onboard electronic equipment failures are a common reason for early satellite failure. But with extended space missions comes the requirement for flawless performance by on-board equipment over a period of years, in a very harsh environment. Ensuring the reliable operation of microcircuits in outer space is an important scientific and economic objective.

The emerging earth observation (EO/IR/SAR) satellites all capture thousands upon thousands of terabytes of data every day, which equates to petabytes every year. And in the future, there will be even more data collected — NASA is planning two space missions called SWOT and NISAR that are expected to produce roughly 100 terabytes of data per day. Not all of this data can be sent back to earth in real time, nor should it, which means that effectively storing it in space is the only way of making this data useful and actionable.

To properly process and handle that data in space, to make that data useful, engineers have discovered acute requirements for data integrity to ensure that data retains the ability to be analyzed in space – or relayed back home for analysis. If data integrity is core to success in space, data storage is equally if not more important, for it’s the foundation on which data can be accessed, stored and analyzed.

Data storage in space needs to be able to endure the rigors of a space mission, from the challenges relating to launch, orbit, and return to earth, and the evolution in data storage reliability has led to an evolution of advanced data storage use cases around us.

Semiconductor memory devices used in outer space, for example, in a satellite, are subjected to severe environmental conditions that may compromise the integrity of the stored data, or cause the memory devices to fail. In many cases, the memory devices are part of a larger embedded system, where the memory device is just one of many devices sharing the same die.

The integrity of the memory devices used in outer space applications is critical because the information stored by the memory devices may be related to critical functions, such as guidance, positioning, and transmitting and receiving data from a ground base station. Furthermore, semiconductor memory devices for use in space applications should remain functional for the lifetime of the satellite, which may be as long as several years. Contrast this with applications where the memory devices are also subjected to harsh operating conditions, such as guidance systems in missiles, but only for a relatively short time period.

Memory technologies

Digital information can be stored in different types of device depending on the use and how frequently the data need to be accessed. Hard disk drives are magnetic devices that allow storing terabytes of data for long time, however speed of access to the data is relatively slow (a few milliseconds). On the other hand, data that are being used by a computer processor to perform an operation need to be accessed on a much faster timescale (nanoseconds). Silicon-based semiconductor memories are categorized into volatile and nonvolatile memories.

Volatile memories, such as static random-access memory (SRAM) and dynamic random-access memory (DRAM), need voltage supply to hold their information while nonvolatile memories, namely Flash memories, hold their information without one. Most devices like smartphones and notebooks currently use a combination of dynamic random-access memory (DRAM) and flash memory, with the former acting as active memory while devices are on, and the latter being used to store data long-term (off or on).

Flash memory is widely used in consumer electronic products such as cell phones and music players. NAND Flash-based solid-state disks (SSDs) are increasingly displacing hard disk drives as the primary storage device in laptops, desktops, and even data centers. However, Flash is slow and has low endurance. The integration limit of Flash memories is approaching; NAND cannot scale down past 10nm while DRAM and SRAM are costly.

New nonvolatile memory technologies are emerging such as magnetic random-access memory (MRAM), spin-transfer torque random-access memory (STT-RAM), ferroelectric random-access memory (FeRAM), phase-change memory (PCM), and resistive random-access memory (RRAM), that combine the speed of static random-access memory (SRAM), the density of dynamic random-access memory (DRAM), and the nonvolatility of Flash memory and becoming very attractive for future memory hierarchies. Western Digital, owner of the SanDisk brand, has unveiled what it calls the “world’s first” 1TB SD card. It’s only a prototype, but already the company is touting the card’s ability to adequately handle 4K, 8K, VR and 360-degree video when it officially becomes available

Radiation effects on memory

One cause of errors in semiconductor memory devices that are used in outer space applications is due to high-energy particles impinging on the memory device. There are several forms of high energy particles in outer space. For example, there are alpha particles and gamma rays, to name a couple. These high-energy particles strike the semiconductor material on which the memory devices are formed with enough energy to cause the generation of electron-hole pairs. The resulting charge carriers are often trapped in the various oxide layers of the memory devices.

In the case of metal oxide semiconductor (“MOS”) transistors, charges trapped in the gate oxide will shift the threshold voltage. Vt, of the transistor. As a result, leakage currents of the transistors, and consequently, of the memory devices may increase. Where the transistor is used as a transfer gate for a conventional memory cell, the increased leakage current may compromise the integrity of the data stored by the data storage node, such as a capacitor, by allowing the charge representing the data to dissipate.

The frequency or number of charges trapped in an oxide layer is proportional to the thickness of the oxide layer. Consequently, oxides having a greater thickness will, on the average, have a greater number of trapped charges.

Radiation hardening

Radiation hardening is process of making electronic components such as momeory resistant to damage or malfunction caused by high levels of ionizing radiation (particle radiation and high-energy electromagnetic radiation), especially for environments in outer space and high-altitude flight, around nuclear reactors and particle accelerators, or during nuclear accidents or nuclear warfare.

Researchers have explored many concepts for low-cost high-density Radiation-Hardened (RH) Non-Volatile Memory (NVM) for the design of systems for use in space environments. The general principles used to be insensitive to single event upsets is to use triple redundant logic and memories with error correcting codes (e.g. Hamming coding). Circuits with large memories and S-RAM based FPGAs should only be used in radiation environments after a careful analysis of single event upset problems. The problem of single event burnout in power MOSFETs can in many cases be resolved by using a de-rating factor of ~2 of the main voltage and current limitations of the power transistor (implies redesign of power supply).

Earlier solutions relied on inefficient hardening techniques, such as radiation hardening by design (RHBD), which weree implemented either in layout or in the application architecture and not in the fabrication process. Many of these solutions are based on redundancy and result in a performance penalty. Moreover, most aerospace applications preclude the use of moving parts, such as the one in a hard disk. Thus, an ultra-high density storage solution is completely lacking.

Efforts over the last two decades to develop a practical NVM solution for space have fallen short of the density and performance needs. A radiation-hard NVM that can achieve high density is needed. Commercial NVMs have greatly increased in density while reducing cost in recent years, creating a gap of more than six orders of magnitude between commercial and RH devices.

Western Digital’s Design for Reliability

Western Digital engineers have been working with companies in space on their approaches to data storage. Using an approach known as Design for Reliability (DFR) has become popularized as a standard engineering practice, which is intended to design reliability into products using state-of-the-art methods. As technology continues to advance and highly complex devices continue to shrink and miniaturize, DFR can ensure high-performance and low-voltage requirements so that new electronic components can overcome various limitations. DFR made leaps and bounds in space technology development, and the fruits of those labors are subtly penetrating more and more products.

Radiation hardened and tolerant memories

Infineon Technologies AG in Munich is introducing radiation-tolerant 256-megabit and 512-megabit NOR non-volatile Flash memory chips for space applications that involve field-programmable gate array (FPGA) configuration, image storage, microcontroller data, and boot code storage.

Qualified to MIL-PRF-38535’s QML-V flow (QML-V equivalent) the devices offer high quality and reliability standard certification for aerospace-grade integrated circuits.

Infineon’s 256-megabit and 512-megabit radiation-tolerant NOR Flash non-volatile memories deliver a low-pin-count, single-chip solution. When used at high clock rates, the data transfer supported by the devices match or exceed traditional parallel asynchronous NOR Flash memories.

The devices are radiation-tolerant to 30 kilorads (Si) biased and 125 kilorads (Si) unbiased. At 125 degrees Celsius, the devices support 1,000 program/erase cycles and 30 years of data retention and at 85 C 10,000 program/erase cycles with 250 years of data retention. Infineon leveraged the 65-nanometer floating gate Flash process technology to develop the radiation-tolerant 256-megabit quad-SPI (QSPI) and 512-megabit dual quad-SPI NOR Flash.

GSI technology introduced high-performance 288Mb SigmaQuad-II+ radiation-hardened SRAM product.” “The RadHard SigmaQuad

Cobham Semiconductor Solutions in Colorado Springs, Colo., is announcing QML V radiation hardened certification of their non-volatile semiconductor memory products. QML V involves especially rugged microelectronics devices that are qualified for space applications.

The MRAM-based product offering includes a 64-megabit device, UT8MR8M8, offered in a 40-lead quad flatpack, and a 16-megabit device, UT8MR2M8, available in a 40-lead flatpack.

References and resources also include:

https://patents.google.com/patent/US6194276

https://venturebeat.com/2022/03/05/data-storage-from-space-to-earth-3-takeaways-for-the-real-world/

No comments:

Post a Comment