[2309.16075] A review of variable-pitch propellers and their control strategies in aerospace systems

A review of variable-pitch propellers and their control strategies in aerospace systems

The relentless pursuit of aircraft flight efficiency has thrust variable-pitch propeller technology into the forefront of aviation innovation. This technology, rooted in the ancient power unit of propellers, has found renewed significance, particularly in the realms of unmanned aerial vehicles and urban air mobility. This underscores the profound interplay between visionary aviation concepts and the enduring utility of propellers.

Variable-pitch propellers are poised to be pivotal in shaping the future of human aviation, offering benefits such as extended endurance, enhanced maneuverability, improved fuel economy, and prolonged engine life. However, with additional capabilities come new technical challenges. The development of an online adaptive control of variable-pitch propellers that does not depend on an accurate dynamic model stands as a critical imperative. Therefore, a comprehensive review and forward-looking analysis of this technology is warranted.

This paper introduces the development background of variable-pitch aviation propeller technology, encompassing diverse pitch angle adjustment schemes and their integration with various engine types. It places a central focus on the latest research frontiers and emerging directions in pitch control strategies.

Lastly, it delves into the research domain of constant speed pitch control, articulating the three main challenges confronting this technology:

- inadequacies in system modeling

- the intricacies of propeller-engine compatibility, and

- the impact of external, time-varying factors.

By shedding light on these multifaceted aspects of variable-pitch propeller technology, this paper serves as a resource for aviation professionals and researchers navigating the intricate landscape of future aircraft development.

Key points

Here are the key points from the review paper:

- Variable pitch propellers allow aircraft to adapt propeller blade angles to optimize performance across diverse flight conditions. This offers benefits like expanded flight envelope, enhanced maneuverability and fuel economy, prolonged engine life.

- Two main types: hydraulic (larger aircraft) and electric (smaller aircraft/UAVs). Hydraulic uses oil pressure and flyweights to adjust pitch. Electric uses servo motor and gearbox. Both use constant speed governors.

- Used with various engines: turboprop, turboshaft, piston, wankel, DC motors. Matching propeller with engine characteristics is important.

- Precise variable pitch control is critical to realize benefits. PID control widely used but lacks adaptability. More advanced methods like LQG, SMC, INDI, AMPC, neural networks and reinforcement learning being explored for enhanced robustness and adaptability.

- Benefits: improves aircraft endurance, maneuverability, fuel economy. Meets needs for propulsion system similarity studies.

- Key challenges: insufficient system modeling, partial propeller-engine matching, impact of external unsteady factors. Need for adaptive, intelligent control systems that can learn and optimize online in face of uncertainties.

In summary, variable pitch propellers are an enduring but dynamically evolving technology offering substantial benefits if paired with sophisticated control systems. Addressing modeling, compatibility and external factor challenges through data-driven and adaptive techniques can further advance their capabilities.

Propeller Basics

A propeller typically consists of the following key components:

-

Hub: The central part of the propeller, which connects to the aircraft's engine or the propulsion system. The hub is mounted on the engine's driveshaft and provides the structural support for the blades.

-

Blades: Propellers have two or more blades attached to the hub. These blades are aerodynamically designed to generate thrust when they rotate. The number of blades can vary depending on the type of aircraft and its specific requirements.

-

Blade Root: The part of the blade that attaches to the hub. It's the base of the blade and is designed to withstand the mechanical stresses associated with propeller rotation.

-

Blade Tip: The outermost part of the blade, which generates the highest speed and thrust as it moves through the air. Blade tips are often shaped to minimize drag and improve efficiency.

-

Pitch: The angle at which the blades are set relative to the plane of rotation. Adjusting the pitch allows the pilot or operator to control the amount of thrust generated by the propeller.

-

Spinner: In some cases, a spinner is used to cover the hub and the base of the blades for aerodynamic reasons and to improve airflow around the propeller.

-

Propeller Governor: An optional component that helps control the engine's RPM (revolutions per minute) by adjusting the pitch of the blades automatically to maintain a constant RPM.

-

Blade Twist: Propeller blades are often twisted along their length to optimize their performance. The twist helps distribute the load evenly along the blade and improve efficiency.

The design of a propeller can vary significantly depending on the specific application, whether it's for an aircraft, a boat, or another type of vehicle. The dimensions, shape, and materials used in a propeller are carefully engineered to maximize efficiency and performance for the intended use.

The two quantities of interest are the thrust (T) and the torque (Q). We can write expressions for these for a small radial element (dr) on one of the blades:

![]()

![]()

where

![]() and

and ![]()

It is possible to integrate the relationships as a function of r with the appropriate lift and drag coefficients for the local airfoil shape, but determining the induced upwash (ai) is difficult because of the complex helical nature of the trailing vortex system. In order to learn about the details of propeller design, it is necessary to do this.

The Wright brothers, Orville and Wilbur Wright, are credited with inventing and building the world's first successful powered aircraft in the early 20th century. While they are well-known for their pioneering work in aviation, they also made important contributions to propeller design.

The Wright brothers understood that a well-designed propeller was crucial for the efficient and controlled flight of their aircraft. They conducted extensive experiments to determine the optimal shape and dimensions for their propellers. In 1903, they were granted a patent for their propeller design.

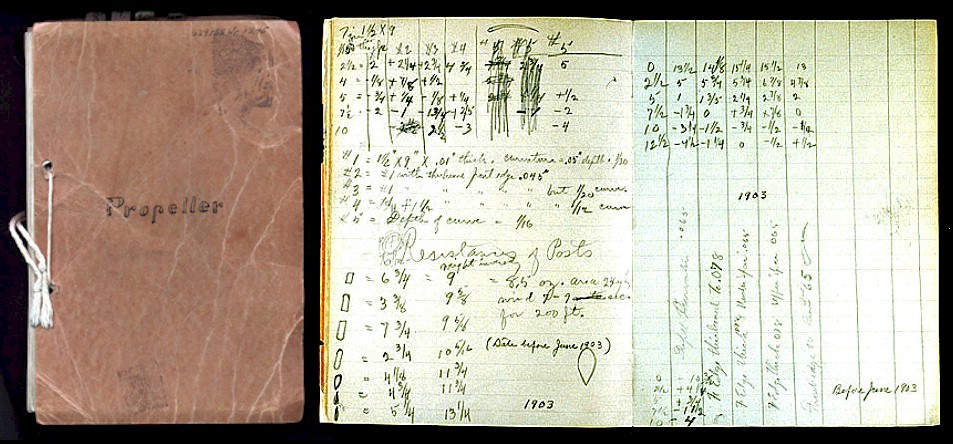

|

| Wright Propeller Lab Workbook |

The patent for the Wright brothers' propeller design is contained in the "Wright Flyer" known as U.S. Patent No. 821,393, and it was filed on March 23, 1903, just a few months before their historic first powered flight on December 17, 1903. The patent described the innovative features of their propeller design, which included a twisted airfoil shape along the length of the blade, a unique curvature, and a specific method of construction.

This modern theory is slightly different from the theory developed by the Wright’s to design their propellers.

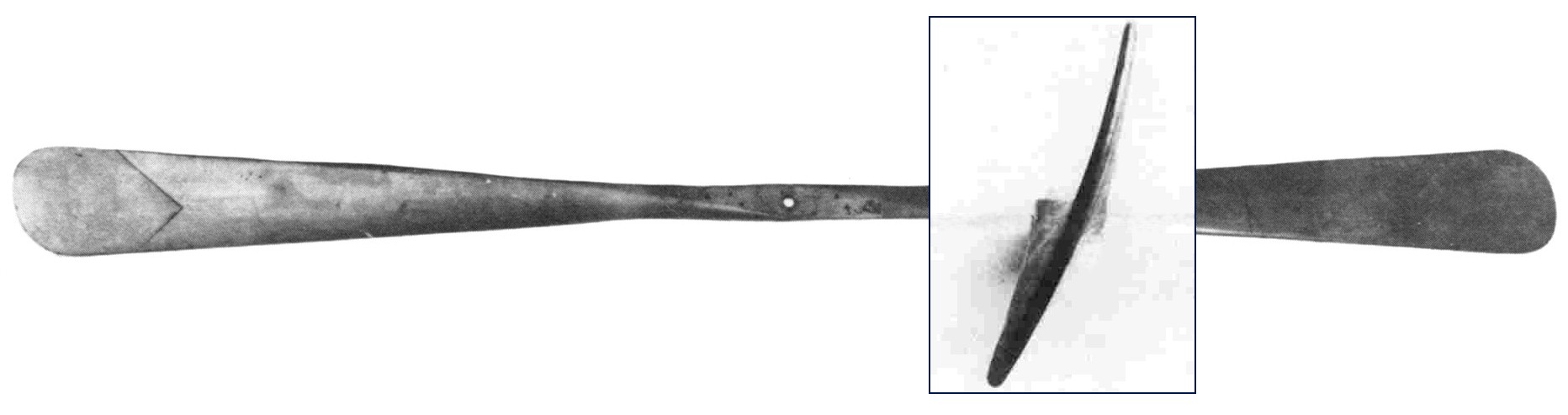

|

| Wright Flyer Propeller, end view, and Dual Mounting Side View |

Propeller Propulsion System

The details of propeller propulsion are very complex because the propeller is like a rotating wing. The Wright brothers are generally credited with being the first ones to look at the problem this way. The Wright propellers had 2 blades. The blades were designed to be long and thin, and a cut through the blade perpendicular to the long dimension gives an airfoil shape. Because the blades rotate, the tip moves faster than the hub.

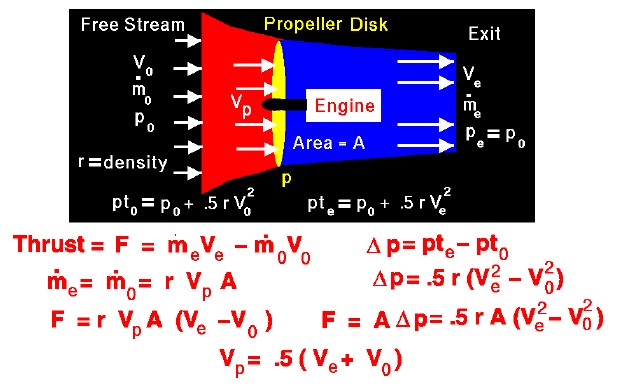

So, to make the propeller efficient, the blades are twisted from hub to tip. The angle of attack of the airfoils at the tip is lower than at the hub because it is moving at a higher velocity than the hub. Of course, these variations make analyzing the airflow through the propeller a very difficult task. Leaving the details to the aerodynamicists, let us assume that the spinning propeller acts like a disk through which the surrounding air passes (the yellow ellipse in the schematic).

From airfoil theory, we know that the pressure over the top of a lifting wing is lower than the pressure below the wing. A spinning propeller sets up a pressure lower than free stream in front of the propeller and higher than free stream behind the propeller. Downstream of the disk the pressure eventually returns to free stream conditions. But at the exit, the velocity is greater than free stream because the propeller does work on the airflow. We can apply Bernoulli’s equation to the air in front of the propeller and to the air behind the propeller. But we cannot apply Bernoulli’s equation across the propeller disk because the work performed by the engine violates an assumption used to derive the equation.

Simple Momentum Theory

Turning to the math, from the basic thrust equation, the amount of thrust depends on the mass flow rate through the propeller and the velocity change through the propulsion system. Let us denote the free stream conditions by the subscript “0”, the conditions at the propeller by the subscript “p”, and the exit conditions by the subscript “e”. The thrust (F) is equal to the mass flow rate (mdot) times the difference in velocity (V).

F = [mdot * V]e – [mdot * V]0

The mass flow through the propulsion system is a constant, and we can determine the value at the plane of the propeller. Since the propeller rotates, we can define an area (A) that is swept out by the propeller of blade length (L). Through this area, the mass flow rate is density (r) times velocity (Vp), times area.

mdot = r * Vp * A

Substitute this value for the mass flow rate into the thrust equation to get the thrust in terms of the exit velocity, entrance velocity, and velocity through the propeller.

F = r * Vp * A * [Ve – V0]

We can use Bernoulli’s equation to relate the pressure and velocity ahead of and behind the propeller disk, but not through the disk. Ahead of the disk the total pressure (pt0) equals the static pressure (p0) plus the dynamic pressure (.5 * r * V0 ^2).

pt0 = p0 + .5 * r * V0 ^2

Downstream of the disk,

pte = p0 + .5 * r * Ve ^2

At the disk itself the pressure jumps

delta p = pte – pt0

Therefore, at the disk,

delta p = .5 * r * [Ve ^2 – V0 ^2]

The force on the propeller disk is equal to the change in pressure times the area (force/area x area = force)

F = delta p * A

If we substitute the values given by Bernoulli’s equation, we obtain:

F = .5 * r * A * [Ve ^2 – V0 ^2]

Combining the two expressions for the the thrust (F) and solving for Vp;

Vp = .5 [Ve + V0]

Note that this thrust is an ideal number that does not account for many losses that occur in practical, high-speed propellers (like tip losses). The losses must be determined by a more detailed propeller theory, which is beyond the scope of these pages. The complex theory also provides the magnitude of the pressure jump for a given geometry. The simple momentum theory, however, provides a good first cut at the answer and could be used for a preliminary design.

Equations to characterize the Propeller

1. Thrust Coefficient

which is often expressed as

![]() where kT is called the thrust coefficient and in general is a function

of propeller design, Re, Mtip and J.

where kT is called the thrust coefficient and in general is a function

of propeller design, Re, Mtip and J.

2. Torque Coefficient

We can follow the same steps to arrive at a relevant expression and functional dependence for the torque or apply physical reasoning. Since torque is a force multiplied by a length, it follows that

![]() where kQ is called the thrust coefficient and in general is a function

of propeller design, Re, Mtip and J.

where kQ is called the thrust coefficient and in general is a function

of propeller design, Re, Mtip and J.

3. Efficiency

The efficiency is given by

4. Power Coefficient

The power required to drive the propeller is

![]()

which is often written using a power coefficient Cp = 2pkQ

![]() then

then

|

| Typical propeller efficiency curves as a function of advance ratio (J=uo/nD) and blade angle(McCormick, 1979) |

|

| Typical propeller power curves as a function of advance ratio (J=uo/nD) and blade angle (McCormick, 1979). |

In aerodynamics and propeller theory, the advance ratio (J) is a critical parameter that characterizes the performance of a propeller. It is defined as:

J = (V / nD)

Where:

- J is the advance ratio

- V is the velocity of the aircraft or the inflow velocity at the propeller disc

- n is the rotational speed of the propeller (in revolutions per minute, RPM)

- D is the diameter of the propeller disc

The advance ratio provides a way to describe the relative importance of the forward speed of the aircraft (or inflow velocity) and the rotational speed of the propeller in determining the performance of the propeller.

The propeller power curve is a plot of the power required or power produced by a propeller as a function of the advance ratio (J). The shape of this curve depends on several factors, including the blade angle, airfoil shape, and other design parameters.

Typically, the propeller power curve has the following characteristics:

-

Minimum Power Point (MPP): There is a point on the curve where the power required to turn the propeller is minimized for a given advance ratio. This is often the point of peak propeller efficiency. The propeller operates most efficiently at or near this point.

-

Climbing and Descending Segments: The power curve will have climbing and descending segments on either side of the MPP. In the climbing segment, as the advance ratio decreases (J increases), more power is required to turn the propeller due to increased airspeed. In the descending segment, as the advance ratio increases (J decreases), more power is required due to decreased airspeed.

-

Maximum Power Point (Max Power): At the highest advance ratios, the power required to turn the propeller increases significantly, leading to a maximum power point. This is often encountered in high-speed flight or when the propeller is operating at high angles of attack.

The blade angle plays a crucial role in shaping the power curve.

Blades with different angles of attack will have different power curves.

A propeller's design aims to optimize the blade angle and airfoil shape

to achieve the desired performance characteristics across a range of

operating conditions. This is why variable pitch propellers expand and extend operating characteristics.

It's important to note that propeller performance is also influenced by factors such as altitude, temperature, and humidity, which can affect air density and, consequently, the performance of the propeller.

For specific power curves and detailed analysis, you would need to refer to the data and research presented in McCormick's 1979 work or other relevant sources on propeller theory and performance.

Medium Altitude Long Endurance UAVs

there are some medium-altitude, long-endurance (MALE) unmanned aerial vehicles (UAVs) that utilize variable pitch propellers:

- MQ-9 Reaper: A widely used MALE

UAV developed by General Atomics Aeronautical Systems. It uses a variable pitch pusher

propeller powered by a TPE331-10 TURBOPROP ENGINE. VPP control is integrated into the engine. This enhances its

endurance and efficiency.

Max Altitude: 50,000 ft (15240m) Max Endurance: 27 hr Max Air Speed: 240 KTAS - Heron TP: An Israeli MALE UAV

with a variable pitch pusher propeller.

endurance of over 45 hours

altitude ceiling of 30,000 ft. - Bayraktar TB2: A Turkish MALE UAV that employs a variable pitch propeller system. It has demonstrated over 27 hours of endurance.

- CH-5: A Chinese MALE UAV by

China Aerospace Science and Technology Corporation. Its variable pitch

propellers are powered by a 170 hp turbocharged piston engine, providing

long endurance.

Max Altitude = 29,528 ft

Max Endurance = 21 hr

Max Airspeed = 298 mph - MQ-1C Gray Eagle: An extended range version of the Predator UAV using a variable pitch pusher propeller.

Max Altitude: 29,000 ft (8839.2m) Max Endurance: 25 hr Max Air Speed: 167 KTAS

Variable pitch propellers allow these MALE UAVs to achieve the high endurance, efficiency and flight envelope they require for their surveillance and reconnaissance missions. The technology is well suited to balance the demands of both loitering at altitude and efficient cruise flight.

Current Pitch Control Methods

The specific control algorithms used for variable pitch propellers in MALE UAVs are often proprietary to the manufacturers. However, based on the general research into variable pitch control, some commonly used approaches include:

- PID control: The most widespread method using proportional, integral and derivative terms to achieve the desired pitch angle. Provides simplicity but lacks adaptability.

- Fuzzy logic control: Allows pitch control based on imprecise inputs and linguistic control rules. Provides some robustness.

- Neural networks: Used to model the complex propeller dynamics and provide predictive pitch control. Offers ability to learn system behavior.

- Model predictive control: Optimizes pitch angles by predicting system behavior over a time horizon using a model. Handles constraints well.

- Reinforcement learning: Optimizes a pitch control policy to maximize reward signals related to objectives like efficiency. Enables online learning.

- Hybrid methods: Combining model-based and learning-based techniques for balanced performance. For example, neural networks with PID or reinforcement learning with model predictive control.

The choice of control algorithm depends on factors like the propeller setup, aircraft performance objectives, environmental conditions, and computational capabilities. Many MALE UAVs likely use proprietary implementations of hybrid control techniques to get the adaptation benefits while ensuring stability and reliability. The ability to optimize efficiency online for long missions would be particularly beneficial.

VPQ unique capabilities

On smaller commercial drones, which have become popular in recent years, the installation of variable pitch propellers is being considered and researched for industrial applications such as large drones and flying mobility. A variable-pitch propeller not only provides higher responsiveness than control by rotational speed alone, but also expands the thrust that can be achieved by optimizing the combination of rotational speed and pitch angle.

A Variable Pitch Quadcopter (VPQ) is a type of quadcopter that features variable pitch propellers. These propellers can change their pitch angle during flight, which allows for more precise control and greater maneuverability compared to traditional fixed-pitch quadcopters. The Aerospace Controls Laboratory, typically found in universities or research institutions, may be involved in the development and research of such advanced aerial vehicles.

Here are some key aspects of a Variable Pitch Quadcopter and how it differs from a standard quadcopter:

-

Variable Pitch Propellers:

- Variable pitch propellers have the ability to adjust the angle of their blades dynamically during flight.

- By changing the pitch of the propellers, a VPQ can generate varying amounts of thrust, making it possible to achieve complex maneuvers and control in different flight conditions.

-

Enhanced Maneuverability:

- Variable pitch allows for rapid changes in thrust and torque, making it more agile and responsive than fixed-pitch quadcopters.

- It can perform acrobatic maneuvers, recover from disturbances, and hover more precisely.

-

Versatility:

- VPQs can adapt to different flight regimes, from hovering and slow flight to high-speed forward flight.

- This adaptability makes them suitable for a wide range of applications, from search and rescue to surveillance.

-

Research and Development:

- Aerospace Controls Laboratories often focus on the development and testing of advanced aerial systems like VPQs.

- Research goals may include improving flight control algorithms, optimizing power efficiency, enhancing stability in challenging environments, and exploring new applications.

-

Control Systems:

- VPQs require sophisticated control systems to manage the variable pitch propellers effectively.

- These control systems often involve advanced algorithms, sensors, and real-time computing to adjust propeller pitch based on flight conditions.

-

Applications:

- VPQs have potential applications in various fields, including military and defense, aerial photography, environmental monitoring, and agricultural surveys.

-

Challenges:

- Designing and building a VPQ can be challenging due to the complexity of the variable pitch mechanism and control system.

- Ensuring the safety and reliability of such aircraft is critical.

The specific research and development projects in an Aerospace Controls Laboratory involving a Variable Pitch Quadcopter may vary, but they typically revolve around improving the performance, control, and applications of these advanced aerial vehicles.

In his thesis, Mark Cutler explores the benefits of using variable-pitch propellers on quadrotor helicopters. He argues that variable-pitch propellers can overcome some of the limitations of fixed-pitch propellers, such as the limited actuator bandwidth and the types of maneuvers possible.

Cutler presents a detailed analysis of the potential benefits of variable-pitch propellers, and supports his analysis with experimental testing. He also presents a nonlinear, quaternion-based control algorithm for controlling a variable-pitch quadrotor helicopter.

Cutler's thesis is a valuable contribution to the field of quadrotor helicopter design and control. His work shows that variable-pitch propellers can significantly improve the performance and capabilities of quadrotor helicopters.

Here are some of the key findings of Cutler's thesis:

- Variable-pitch propellers allow for efficient generation of negative thrust, which is not possible with fixed-pitch propellers.

- Variable-pitch propellers substantially increase the maximum rate of thrust change.

- The use of variable-pitch propellers enables new types of maneuvers, such as aggressive forward flight and agile hovering.

- Cutler's nonlinear, quaternion-based control algorithm is able to effectively control a variable-pitch quadrotor helicopter, even under challenging conditions.

Cutler's thesis has had a significant impact on the field of quadrotor helicopter design and control. His work has inspired other researchers to develop new variable-pitch quadrotor helicopters and control algorithms. Variable-pitch quadrotor helicopters are now widely used in a variety of applications, including aerial photography, inspection, and delivery.

Optimal variable pitch control methods

Optimal variable pitch propeller control methods for Medium Altitude Long Endurance (MALE) Unmanned Aerial Vehicles (UAVs) are crucial for achieving efficient and effective flight performance. Variable pitch propellers allow UAVs to adapt to different flight conditions, maximize endurance, and improve overall mission capabilities. Here are some optimal control methods for variable pitch propellers on MALE UAVs:

-

Constant-Speed Propeller Control (CSPC): This control method maintains a constant rotational speed of the propeller blades. This is suitable for cruising and maintaining a fixed airspeed, as it provides consistent thrust. It can be combined with other control methods for better performance.

-

Variable-Pitch Control (VPC): VPC allows for the adjustment of the propeller blade pitch angle in real-time. By varying the pitch angle, the UAV can optimize thrust, efficiency, and speed for different flight phases. For example, a high pitch angle can be used for climbing, while a low pitch angle can be used for cruising.

-

Constant Angular Velocity Control (CAVC): This method maintains a constant angular velocity (rpm) of the propeller, which is particularly useful for applications where a fixed rotational speed is critical, such as in surveillance missions requiring steady camera footage.

-

Optimal Control Algorithms: Implementing advanced control algorithms, such as PID (Proportional-Integral-Derivative) controllers or more sophisticated model-based controllers, can help optimize variable pitch propeller performance. These algorithms can continuously adjust the propeller pitch based on various parameters such as airspeed, altitude, and payload weight to maximize efficiency and endurance.

-

Flight Control System Integration: Integration with the overall flight control system is essential. Variable pitch propeller control should work in harmony with other flight control elements like the autopilot, navigation system, and mission-specific software. This integration allows for coordinated and optimized control strategies.

-

Mission-Adaptive Control: Develop control algorithms that adapt to the specific mission requirements of the MALE UAV. For instance, for a reconnaissance mission, the control system may prioritize endurance and altitude holding, while for a search-and-rescue mission, it may prioritize rapid climbing and descent.

-

Energy Management: Implement energy management strategies to balance energy consumption and generation. This includes optimizing the use of onboard power sources (e.g., batteries or generators) and the propulsion system to maximize overall endurance.

-

Real-Time Sensor Feedback: Utilize real-time data from onboard sensors (e.g., airspeed, altitude, temperature) to adjust the variable pitch propeller settings on the fly. This allows the UAV to adapt to changing environmental conditions and optimize its performance accordingly.

-

Fail-Safe Mechanisms: Incorporate fail-safe mechanisms that can revert the variable pitch propeller to a safe configuration in case of system malfunctions or emergencies, ensuring the UAV can safely return to base or complete its mission.

-

Testing and Simulation: Extensive testing and simulation are essential to fine-tune and validate control methods for variable pitch propellers. This helps in identifying and addressing potential issues before deployment.

Suggested Approaches to Optimality

This review paper does not explicitly propose a single optimal variable pitch control method. However, based on the analysis and discussion presented, some key recommendations can be summarized:

- Adaptive and intelligent control methods are needed to handle changing dynamics, uncertainties and disturbances. This includes techniques like incremental nonlinear dynamic inversion (INDI), adaptive model predictive control (AMPC), and reinforcement learning (RL).

- Hybrid hierarchical approaches combining model-based and learning-based techniques appear promising to balance performance, stability and adaptability. For example, INDI with neural networks or RL combined with model predictive control.

- Control techniques that can continuously learn and optimize online in real-time flight are critical to maximize efficiency across long missions in dynamic conditions. RL and adaptive critics are highlighted in this regard.

- Addressing challenges in modeling, engine-propeller compatibility, and external factors is pivotal through data-driven and adaptive control techniques. This reduces reliance on fixed analytical models.

- Cascaded, hierarchical control architectures allowing integrated management of various sub-systems and flight modes are beneficial for comprehensive control.

In summary, the paper recommends adaptive, intelligent and hierarchical control schemes with online learning and optimization capabilities as the most promising direction for advanced variable pitch propeller control on complex aircraft. A mix of model-based and data-driven techniques is advisable.

Adaptive

and intelligent control methods

Adaptive and intelligent control methods for variable pitch propellers (VPP) are crucial to efficiently handle changing dynamics, uncertainties, and disturbances in marine or aerospace applications. These techniques help optimize performance and ensure stability. Here's an overview of how each of the methods you mentioned can be applied:

-

Incremental Nonlinear Dynamic Inversion (INDI): INDI is a model-based control technique that can be adapted for VPP control. It involves the following steps:

- System Modeling: Develop a dynamic model of the VPP system, including the propeller, power source, and any other relevant components.

- Dynamic Inversion: Invert the dynamic model to obtain the desired control inputs that will produce the desired system response.

- Adaptation: Incorporate adaptive mechanisms to account for changing dynamics and uncertainties. This can involve online parameter estimation or model adaptation algorithms.

- Disturbance Rejection: Implement techniques for handling disturbances, such as disturbance observers or feedforward control.

INDI can effectively handle changing dynamics by continuously updating the control inputs based on the current system state and adapting to uncertainties and disturbances.

-

Adaptive Model Predictive Control (AMPC): AMPC is a control strategy that uses a predictive model of the system to optimize control inputs over a finite time horizon. For VPP, AMPC can be applied as follows:

- Model Development: Create a predictive model of the VPP system that captures its dynamics and uncertainties.

- Prediction and Optimization: Predict the future system behavior over a horizon and optimize control inputs to achieve desired performance while considering disturbances.

- Adaptation: Incorporate adaptive elements into the model to account for changing dynamics and uncertainties. This can include updating model parameters or using adaptive constraints in the optimization.

AMPC's predictive nature allows it to handle changing dynamics and uncertainties by continuously adjusting the control inputs based on the updated model and feedback.

-

Reinforcement Learning (RL): RL is a data-driven approach that can be applied to VPP control, although it typically requires a substantial amount of data for training. Here's how RL can be used:

- Environment Modeling: Create a simulator or a digital twin of the VPP system to serve as the RL environment.

- Training: Train an RL agent to interact with the environment and learn optimal control policies through exploration and reward maximization.

- Adaptation: RL agents inherently adapt to changing dynamics and disturbances during training. However, fine-tuning or retraining may be necessary as the system evolves or encounters significant changes.

RL is particularly effective when dealing with complex and uncertain VPP systems, but it requires careful consideration of safety and exploration during training.

In summary, these control methods—INDI, AMPC, and RL—can be adapted

for variable pitch propeller control to address changing dynamics,

uncertainties, and disturbances. The choice of method depends on the

specific application, available data, and computational resources, as

each method has its strengths and limitations.

Potential Performance Gains

Adopting optimal and adaptive variable pitch control techniques could potentially provide significant performance improvements compared to conventional fixed gain controllers:

- Fuel efficiency gains of 10-20% reported in some studies by optimizing pitch angles for minimum power consumption across flight envelopes.

- Increased aircraft endurance by 5-15% through power optimization and expanded flight envelopes.

- Enhanced maneuverability and precision in tracking control inputs due to faster pitch actuation response and reversal capabilities.

- Ability to handle constraints such as engine speed limitations more effectively by predictive control algorithms.

- Up to 30-50% reduction in modeling errors and uncertainties by relying on data-driven adaptation rather than fixed analytical models.

- Improved stability and robustness in aggressive maneuvers and turbulence by adaptation to dynamic conditions.

- Potential elimination of trim requirements and simpler autopilot integration by neutralizing modeling errors adaptively.

The scale of improvements depends on the specific aircraft, with most gains coming from long-endurance UAVs and multi-rotors. But even manned aircraft could see benefits in efficiency and handling qualities from optimal variable pitch control. The key is having the advanced control architectures to fully exploit the capabilities.

Sources

-

Spakovsky Waitz. Thermodynamics and Propulsion 11.7 Propellers

- Cutler, M., “Design and Control of an Autonomous Variable-Pitch Quadrotor Helicopter,” Master's thesis, Massachusetts Institute of Technology, Department of Aeronautics and Astronautics, 2012. https://dspace.mit.edu/handle/1721.1/77106

- Cutler, M., and How, J. P., “Actuator Constrained Trajectory Generation and Control for Variable-Pitch Quadrotors,” AIAA Guidance, Navigation, and Control Conference (GNC), Minneapolis, Minnesota: 2012, pp. 1–15.

- Cutler, M., Ure, N. K., Michini, B., and How, J. P., “Comparison of Fixed and Variable Pitch Actuators for Agile Quadrotors,” AIAA Guidance, Navigation, and Control Conference (GNC), Portland, OR: 2011, pp. 1–17.

- Michini, B., Redding, J., Ure, N. K., Cutler, M., and How, J. P., “Design and Flight Testing of an Autonomous Variable-Pitch Quadrotor,” IEEE International Conference on Robotics and Automation (ICRA), 2011, pp. 2978–2979.

- Jan Gebauer, Renata Wagnerová, Pavel

Smutný, Petr Podešva, "Controller design for variable pitch propeller

propulsion drive," IFAC-PapersOnLine, Volume 52, Issue 27, 2019, Pages

186-191, ISSN 2405-8963, https://doi.org/10.1016/j.ifacol.2019.12.754.

(https://www.sciencedirect.com/science/article/pii/S240589631932703X)

Abstract: This article describes the structure of variable pitch

propulsion drive controller (VPPDC) and its capabilities. The control

algorithm is applicable for multirotor flying platforms with variable

pitch propellers installed. The VPPDC is an extension of standard

propulsion drive which improves its efficiency and extends the flight

time. The algorithm is based on knowledge of accurate propeller and

brushless motor properties. Its structure is described in Simulink.

Keywords: UAV propulsion; variable pitch propeller; propeller propulsion - T. Henderson and N. Papanikolopoulos, "Adaptive Control of Variable-Pitch Propellers: Pursuing Minimum-Effort Operation," 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 2020, pp. 7470-7476, doi: 10.1109/ICRA40945.2020.9197208.

- Ony Arifianto, Mazen Farhood "Optimal control of a small fixed-wing UAV" Department of Aerospace and Ocean Engineering, Virginia Tech, Blacksburg, VA 24061, USA https://par.nsf.gov/servlets/purl/10084616

The paper focuses on the control of a small fixed-wing unmanned aerial vehicle (UAV) along trajectories. The trajectories are generated in real-time from a library of pre-specified motion primitives. Two concatenated primitive trajectories are considered: one formed from seven primitives and exhibiting a figure-8 geometric path and another composed of a Split-S maneuver that settles into a level-turn trim trajectory. Switched control systems stemming from ℓ2 -induced norm synthesis approaches are designed for discrete-time linearized models of the nonlinear UAV system. These controllers are analyzed based on simulations in a realistic operational environment and are further implemented on the physical UAV - Yuto Naoki, Kentaro Yokota, Sakahisa Nagai, Hiroshi Fujimoto, "Achievable Thrust Expansion Control at Current Saturation of Variable-Pitch Propeller for Drones", IFAC-PapersOnLine, Volume 55, Issue 27, 2022, Pages 247-252, ISSN 2405-8963, https://doi.org/10.1016/j.ifacol.2022.10.520. (https://www.sciencedirect.com/science/article/pii/S2405896322025733)

Abstract:In this paper, it is experimentally verified that, in the current saturation region of a variable-pitch propeller motor, the control method using simple frequency-separated command values for rotational speed and pitch angle causes an inverse response in transient conditions, and we attempt to explain this response by a linearized model including unstable zero. Basing on the model, we proposed a control method in which the pitch angle is controlled by a first-order filter while the maximum current is applied. The proposed method enables control design with a trade-off between initial undershoot and settling time with one parameter. The effectiveness of the proposed method is verified by simulation and experiment.

Keywords: aerial robot; modeling; variable pitch propeller; thrust control; transient response; unstable zero; current saturation - Robert A. McDonald, "Optimal Propeller Pitch Scheduling and Propeller--Airframe Matching for Conceptual Design"AIAA 2015-3190 Session: Transformational Flight - Electric PropulsionPublished Online:18 Jun 2015 https://doi.org/10.2514/6.2015-3190Jan Gebauer, Renata Wagnerová, Pavel Smutný, Petr Podešva, "Controller design for variable pitch propeller propulsion drive," IFAC-PapersOnLine, Volume 52, Issue 27, 2019, Pages 186-191, ISSN 2405-8963, https://doi.org/10.1016/j.ifacol.2019.12.754. (https://www.sciencedirect.com/science/article/pii/S240589631932703X) Abstract: This article describes the structure of variable pitch propulsion drive controller (VPPDC) and its capabilities. The control algorithm is applicable for multirotor flying platforms with variable pitch propellers installed. The VPPDC is an extension of standard propulsion drive which improves its efficiency and extends the flight time. The algorithm is based on knowledge of accurate propeller and brushless motor properties. Its structure is described in Simulink.

Keywords: UAV propulsion; variable pitch propeller; propeller propulsionhttps://www.scribd.com/doc/314572260/Spakovsky-Waitz-Thermodynamics-and-Propulsion

No comments:

Post a Comment