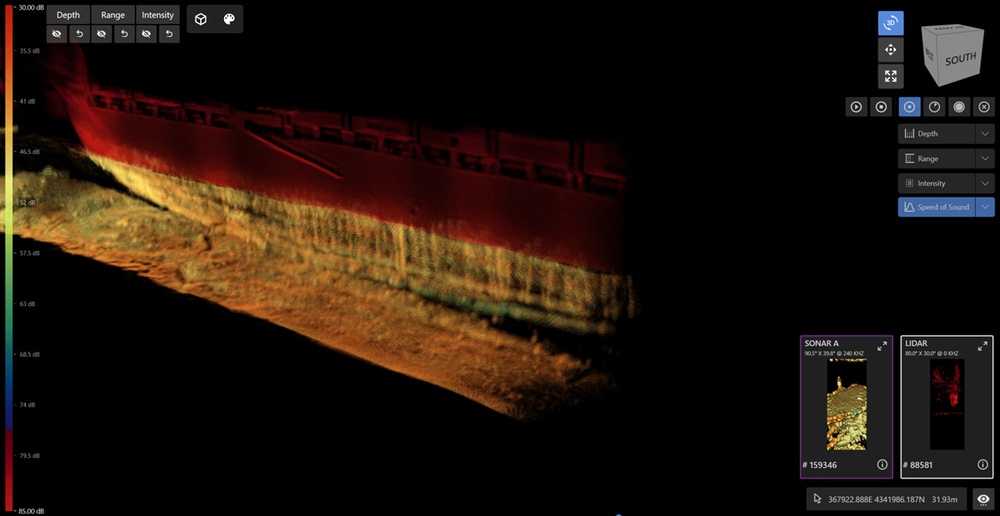

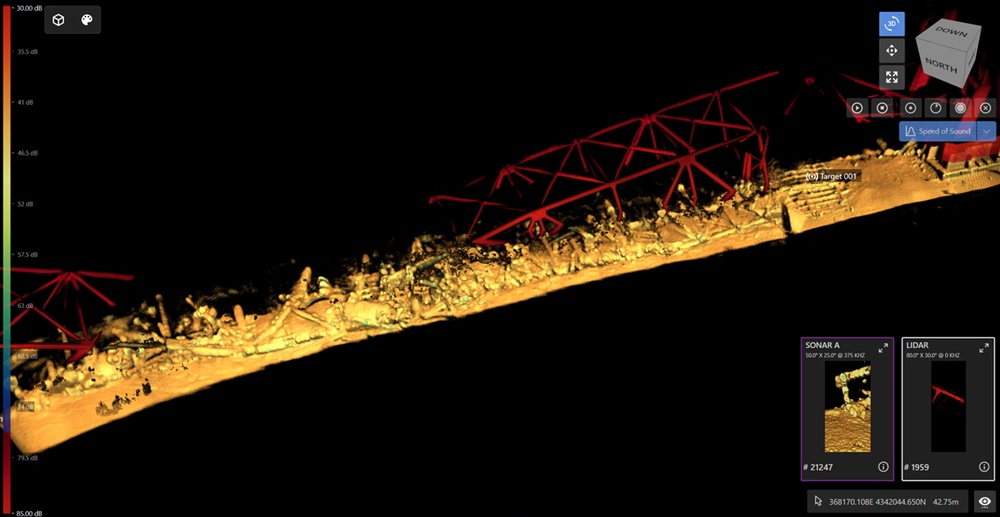

Navy 3D sonar images reveals challenges of salvaging Baltimore's Francis Scott Key Bridge wreckage

This imagery, supplied by the U.S. Navy’s Naval Sea System Command

(NAVSEA) Supervisor of Salvage and Diving (SUPSALV), shows the wreckage

resting at the bottom of the river where the Francis Scott Key Bridge

once stood. These 3D images show the sheer magnitude of the very

difficult and challenging salvage operation ahead. The underwater sonar

imaging tool, known as CODA Octopus [DAVD Echoscope], is the primary survey tool used by

divers, with visibility clouded to just one to two feet because of the

four to five feet of mud and loose bottom of the Patapsco River.

Divers are forced to work in virtual darkness, because when lit, their

view is similar to driving through a heavy snowfall at night with

high-beam headlights on. So murky is the water, divers must be guided

via detailed verbal directions from operators in vessels topside who are

viewing real-time CODA imagery. No usable underwater video exists of

the wreckage, because as one Navy diver stated, “there’s no need take

video of something you can’t even see.” [(Photos courtesy of U.S.

Navy’s Naval Sea System Command (NAVSEA) Supervisor of Salvage and

Diving (SUPSALV)]

Maryland divers guided by sonar due to extreme poor visibility in Key Bridge repair | Fox News

Amid ongoing salvage operations in the aftermath of Baltimore’s Francis Scott Key Bridge collapse last week, divers are relying on sonar technology to guide them underwater.

Colonel Estee S. Pinchasin, Commander of the U.S. Army Corps of Engineers in Baltimore, said Wednesday that the "Coda Octopus" [DAVD Echoscope] is the primary survey tool used by the divers.

Echoscope® XD on-water Demonstration, April 5th 2017: Collected during Ocean Business 2017 in Southampton, this real-time 3D data shows rows of quay pilings and illustrates how the 2nd row is visible using the unique and most advanced real-time 3D sonar in the world, the new Echoscope® XD with a wider field of view at 240 kHz (90° x 44°)

Coda Octopus Group Reports that its Echoscope® Technology used as the Primary Survey Tool in the Francis Scott Key Bridge ongoing salvage operations. :: Coda Octopus Group, Inc. (CODA)

ORLANDO, FL, April 02, 2024 (GLOBE NEWSWIRE) -- Coda Octopus Group, Inc. (“CODA” or the “Company”) (Nasdaq: CODA), a global market leader in 3D/4D/5D/6D imaging sonar technology for real time subsea intelligence and cutting-edge diving technology, today reported that its Echoscope® technology is being used on the ongoing salvage operations. The news highlighting this can be found here.

Commenting on this, Blair Cunningham, CODA’s President of Technology, stated “we are humbled and pleased that Coda Octopus and its technology can play a part as the primary survey tool in these ongoing operations, and I am pleased that I can be onsite assisting in the ongoing operations. As noted by SUPSALV in the article referred to above, the conditions are challenging and compounded by poor visibility water conditions …the Echoscope® “is the primary survey tool used by divers, with visibility clouded to just one to two feet because of the four to five feet of mud and loose bottom of the Patapsco River”.

About Coda Octopus Group, Inc.

The Company, founded in 1994, is an established supplier to the Underwater/Subsea market. It supplies a range of hardware and software solutions to this market which includes key proprietary real time 4D/5D/6D imaging sonars, marketed under the name Echoscope® and Echoscope PIPE® addressing the underwater imaging sensor market along with new generation diving technology, Diver Augmented Vision Display (DAVD) system. The Company’s Echoscope PIPE® sonar generates real-time 3D/4D/5D images of moving objects underwater including in zero visibility water conditions. The Echoscope® technology is used globally for numerous applications in both the commercial offshore market and defense underwater markets. Applications for the Echoscope® technology include complex mapping underwater, subsea intervention, subsea asset placements, salvage and recovery, search and rescue, offshore renewables cable installations and surveys, marine construction, subsea infrastructure installation, mining applications, robotics (3D Perception and Depth), breakwater construction and monitoring, decommissioning, diving applications and port and harbor security.

The recently launched new generation of diving technology, DAVD, has the potential to change the way global diving operations are performed (both in the Defense and Commercial space) because it is a fully integrated singular system for topside control and fully connected diver HUD system, allowing both the topside and diver to share a range of critical information and visualize the same underwater scene. Furthermore, the DAVD integrates the Company’s sonar technology, which allows dive operations to be performed in zero visibility conditions, a common problem that besets these operations.

The Company also includes two discrete Defense engineering businesses Coda Octopus Martech Ltd (UK based) and Coda Octopus Colmek, Inc. (US based) whose primary business model is to supply sub-assemblies into broader mission critical programs in the capacity of sub-contractors to the Prime Defense Contractors. Their scope of supply under these programs typically includes concept, design, prototype, manufacturing, and post-sale support. This gives them the opportunity to have repeat orders for these sub-assemblies through the life of these programs.

For further information, please visit http://www.codaoctopusgroup.com or contact us at coda@codaoctopusgroup.com.

Contact:

Source: Coda Octopus Group, Inc. Released April 2, 2024

|

| subsea2020.com |

- Underwater positioning

- ROV intervention work

- Port Security

- Ultra high-res mapping

- Inspection, Repair and Maintenance

- Cable or mattress laying

- Marine construction

With over 16,000 beams per acoustic transmission and a frame rate of over 10 pings per second, Echoscope® sonars provide unique underwater acoustic movie imagery using patented 3D rendering techniques. The Echoscope is proven to save vessel time and increase productivity during zero visibility subsea conditions.

Each Echoscope 3D sonar is supplied with a topside USE software package for integration with motion, heading and positioning systems. The combination of Echoscope and USE software is changing the mode of many subsea operations around the globe.

Compact, portable and rapidly deployed, the Echoscope is available in single-frequency or dual-frequency systems. Specialized hardware/software systems and technical consulting for seamless integration with the Echoscopeare are readily available. Contact us more for case studies or more information.

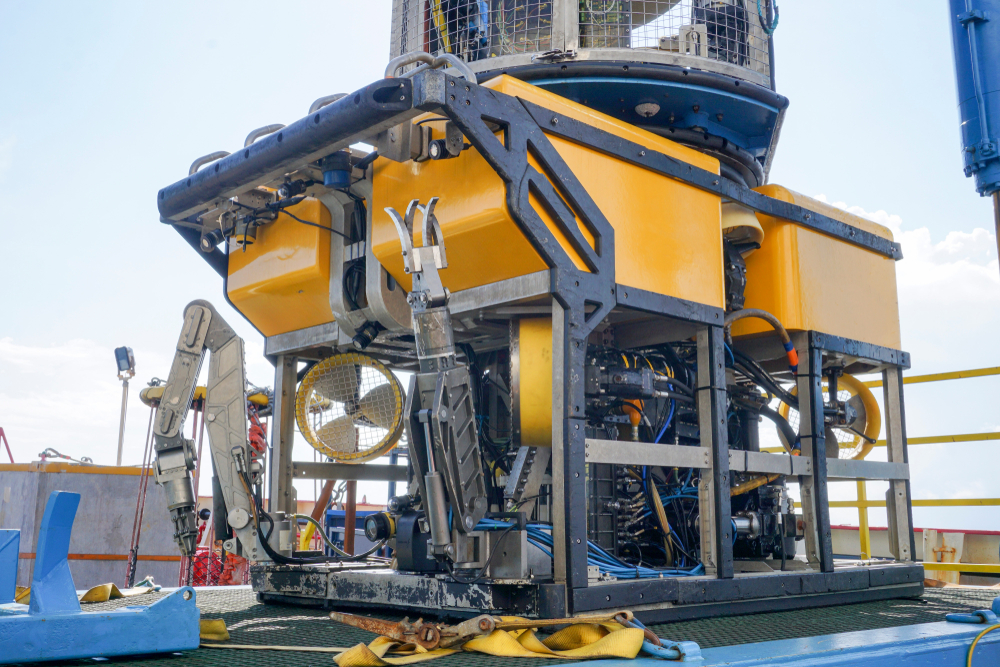

Underwater robots: Navigating the depths of the maritime industry

Find out how subsea robots are helping the industry explore and operate in the world’s harshest conditions.

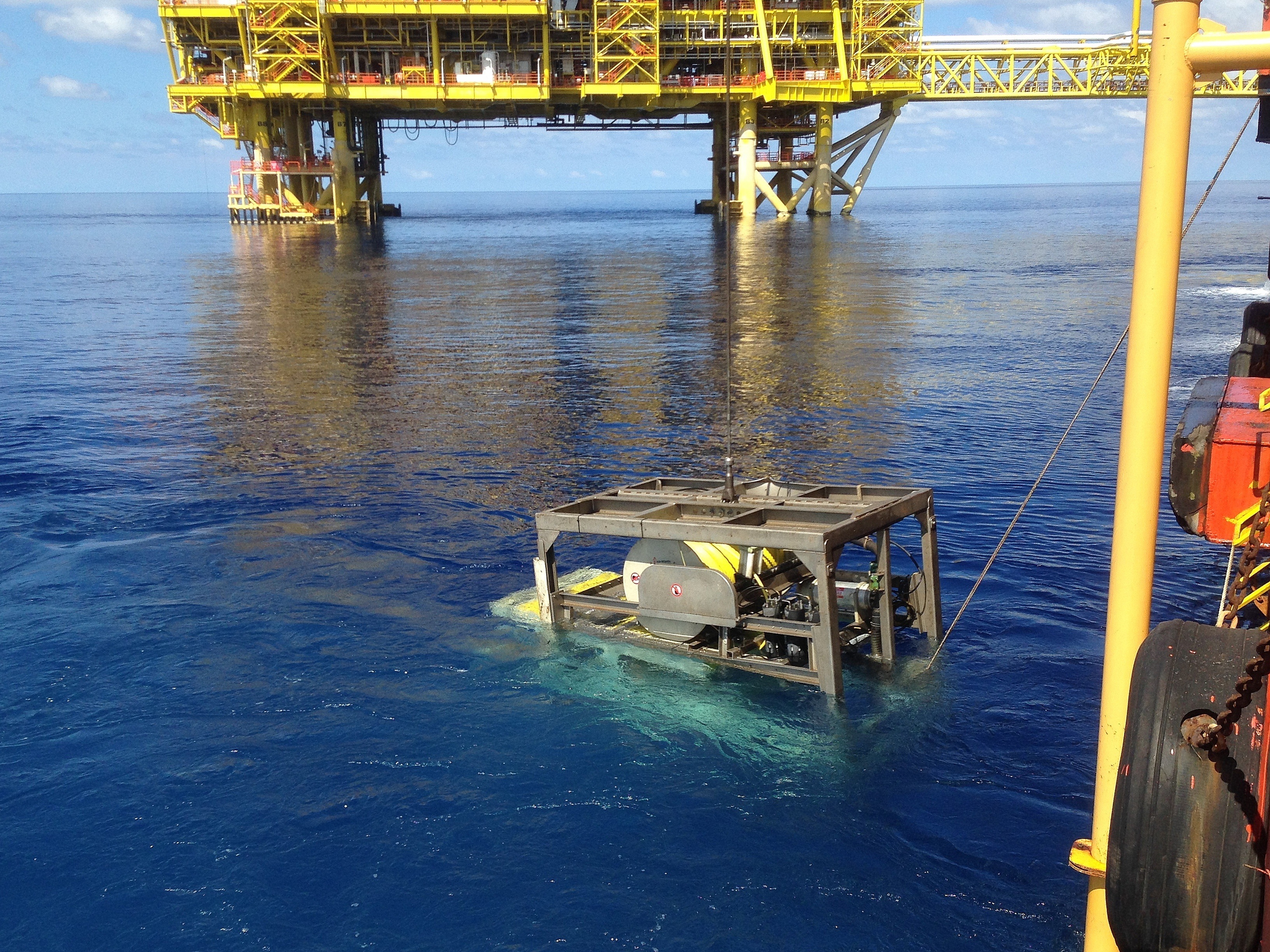

Underwater robots have emerged as pivotal tools in various sectors for work that is considered too dangerous or expensive for human divers. These sophisticated machines, often referred to as underwater drones, subsea robotics, remotely operated vehicles (ROVs), and autonomous underwater vehicles (AUVs), have significantly expanded our capacity to explore and interact with the underwater world.

This article provides a comprehensive overview of underwater robots, delving into their uses, advantages, limitations, and the diverse types available in the market. Business, government, and non-profit leaders should be equipped with the factors to consider before investing in subsea robots such as an understanding of the complementary solutions, operational skills required, components, maintenance requirements, and expected lifespan of underwater robots.

What is an underwater robot?

At its core, an underwater robot is a technologically advanced machine designed for submerged operations. These robots range from remotely operated vehicles (ROVs) to autonomous underwater vehicles (AUVs), each equipped with specialized functionalities to perform tasks beneath the water surface. Underwater robots are often equipped with cameras, sensors, and application-specific tools (grippers, welding torches, etc.), enabling them to navigate, gather data, and sometimes manipulate objects in the aquatic environment.

What are the primary uses of underwater robots?

Underwater robots serve a myriad of purposes across various industries. Some of their primary uses include:

Exploration and mapping

These robots are instrumental in underwater exploration, helping to map ocean floors, coral reefs, and underwater geological structures.

Scientific research

In the realm of marine biology and oceanography, underwater drones provide invaluable data on marine ecosystems, water quality, and climate change impacts.

Industrial applications

In sectors like oil and gas, underwater robots perform critical tasks such as inspecting and repairing subsea infrastructure.

Military and defense

ROVs and AUVs are used for mine detection, surveillance, and, in some cases, recovery operations. Robots can protect naval soldiers from some of the most hazardous underwater applications.

Salvage operations

Underwater robots assist in locating and recovering objects or wreckage from the seabed. These operations are some of the most dangerous tasks for humans underwater.

What are the advantages of underwater robots?

The deployment of underwater robots in various domains brings a multitude of benefits, from safety to new capabilities. Key advantages include:

Enhanced safety and accessibility

One of the primary benefits of using underwater robots is the significant reduction in risk to human life. In environments that are hazardous or inaccessible to humans, such as deep-sea exploration, underwater mining, or tasks in contaminated waters, ROVs can operate effectively without the inherent risks associated with human divers. This capability not only ensures safety but also allows exploration and work in previously unreachable depths.

Cost efficiency and time savings

Underwater robots can operate continuously for extended periods, unlike human divers, who are limited by factors like decompression times and fatigue. This extended operational capability leads to more work being completed in a shorter timeframe, thereby optimizing efforts and reducing costs associated with long-term underwater missions. Furthermore, the deployment of underwater robots eliminates the need for extensive support systems, such as decompression chambers and support staff, required for human divers.

High precision and reliability

Equipped with state-of-the-art technology, subsea robots offer a high degree of precision in tasks such as underwater mapping, sampling, and structural inspection. Advanced sensors and imaging technology enable them to collect high-resolution data and imagery, providing valuable insights into the underwater environment. This precision is crucial in industries like oil and gas, where accurate data is essential for safe and effective operations.

Enhanced data collection and monitoring capabilities

Underwater AUVs are instrumental in continuous monitoring and data collection, vital for environmental studies, climate change research, and monitoring the health of marine ecosystems. They can be equipped with various scientific instruments to measure parameters like water temperature, salinity, and pressure, which are essential for understanding oceanographic and environmental conditions.

Innovative applications and flexibility

The versatility of underwater robots and drones allows for their use in a wide range of applications, such as:

- Scientific research

- Environmental monitoring

- Military operations

- Search and rescue missions

- Industrial inspections

This flexibility makes them invaluable assets across numerous sectors. Moreover, the ongoing advancements in robotics technology continually expand the scope and capabilities of these machines, enabling more innovative and complex applications, such as AI-powered exploration and analysis.

In summary, subsea robots offer a compelling combination of safety, efficiency, precision, and versatility, making them indispensable tools in modern underwater operations. Their continued evolution is poised to continue impacting how we explore, study, and interact with the underwater world.

What are the limitations of underwater robots?

While underwater robots and drones are invaluable in many aspects, they do have certain limitations that need to be considered. Understanding these challenges is crucial for effectively selecting and utilizing subsea robots.

Technical challenges and operational complexities

One of the primary limitations of underwater robots, particularly autonomous underwater vehicles (AUVs), is the complexity of operating in a dynamic and often unpredictable underwater environment. Some factors can pose significant challenges, such as:

- Strong underwater currents

- Varying water pressure at different depths

- Obstacles like rocks or shipwrecks

Additionally, underwater communication is limited, as GPS signals do not penetrate water, requiring alternative navigation methods like sonar or acoustic positioning.

Dependency on sophisticated technology and expertise

The operation of underwater robots requires sophisticated technology and specialized knowledge. This dependency means that a high level of expertise is required for their deployment, operation, and maintenance. Such expertise is not always readily available, which can be a barrier, especially in remote or less technologically advanced regions.

Environmental impact concerns

While underwater robots are used for environmental monitoring and research, there is a concern about their impact on marine ecosystems. The presence of robots in sensitive or protected marine areas can potentially disturb marine life. Therefore, careful consideration and planning are needed to minimize any negative ecological impacts.

High initial investment and maintenance costs

The cost of acquiring, deploying, and maintaining subsea robots can be substantial. Advanced models equipped with sophisticated sensors, propulsion systems, and durable materials for deep-sea exploration can be particularly expensive. Additionally, regular maintenance is essential to ensure their functionality and longevity, which adds to the overall cost.

Battery life and power limitations

The endurance of underwater drones is often limited by battery life, especially for AUVs. Long missions or operations at great depths require substantial power, and battery technology constraints can limit operational time and range. While tethered robots like ROVs can draw power from the surface, this tether can restrict their range and maneuverability.

Data management challenges

The large volumes of data collected by underwater robots can present challenges in terms of storage, transmission, and analysis. Efficiently managing and interpreting this data requires advanced data processing capabilities and can be time-consuming and resource-intensive.

In conclusion, while subsea robots offer remarkable capabilities, they are not without limitations. Addressing these challenges through technological advancements and strategic planning is essential for maximizing the potential of these sophisticated tools in exploring and operating in the underwater world.

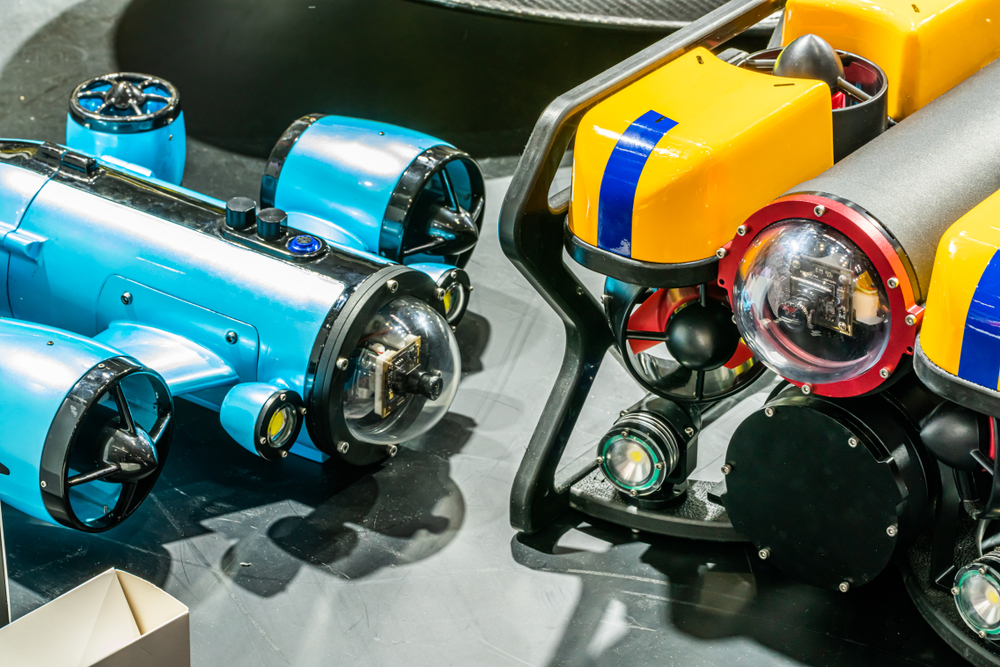

What are the different types of underwater robots?

Underwater robots and drones, integral tools in marine exploration and industrial applications, come in various forms, each designed to meet specific requirements of the underwater environment. The two primary categories are remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs), each with distinct capabilities and uses.

Remotely operated vehicles (ROVs)

ROVs are tethered underwater robots that are controlled remotely from a surface vessel. The tether, or umbilical, provides power and transmits data and commands between the ROV and the operator. This direct control allows for real-time operation and monitoring.

There are different types of ROVs, ranging from small, agile vehicles used for scientific research to large, powerful systems equipped for heavy-duty tasks like drilling support and construction in the oil and gas industry. Observation ROVs are typically smaller and used for tasks such as underwater filming, archaeological surveys, and environmental monitoring. Work-class ROVs, larger and more powerful, are equipped with manipulator arms to perform complex tasks like cutting, welding, or valve operation.

The key advantage of ROVs is the direct control and real-time data transmission, allowing for immediate responses to visual feedback. However, their operational range is limited by the length of their tether, and managing the umbilical can be challenging in complex underwater environments.

Autonomous underwater vehicles (AUVs)

AUVs operate independently without a physical connection to a surface vessel. They are pre-programmed to perform specific tasks and can make decisions based on sensor input. After completing their mission, they return to a predetermined location for data retrieval and recharging.

AUVs vary in size and capability, from small, portable units used for shallow-water surveys to large, sophisticated vehicles capable of deep-sea missions. They are extensively used in scientific research for tasks like seabed mapping, water sampling, and environmental monitoring. In the commercial sector, AUVs are used for pipeline inspection, site surveys, and mineral exploration.

AUVs offer greater freedom of movement and can cover large areas without the constraints of a tether. This autonomy makes them ideal for extensive survey missions. However, their operation requires careful pre-mission programming, and they are limited by battery life and data storage capacity.

Hybrid systems and emerging technologies

There are also hybrid systems that combine features of ROVs and AUVs. These vehicles can operate autonomously and under remote control, offering flexibility for various tasks.

Advances in robotics and AI are leading to the development of smarter, more adaptable underwater robots. These include gliders that use changes in buoyancy for propulsion and micro-robots designed for specific tasks like environmental monitoring or underwater equipment maintenance.

The field of underwater robotics is diverse, with each type of robot offering unique capabilities tailored to specific tasks and environments. The ongoing development of these technologies continues to expand the possibilities and effectiveness of underwater exploration and operations.

How big is the market?

The market for underwater robots has been experiencing substantial growth. Factors driving this growth include increased demand in sectors like maritime security, offshore energy, and scientific research. The continual advancements in technology also play a crucial role in expanding the market reach of these robots.

The market for underwater robots and drones is valued at an estimated (USD) $4.49 billion. A healthy CAGR of 14.5% is expected from 2023 to 2030.

What should you consider if you want to invest in an underwater robot?

Investing in underwater AUVs and ROVs is a significant decision that requires careful consideration of several vital factors. These factors ensure that the investment aligns with specific operational needs and offers the best return on investment.

Define your operational requirements

- Purpose and application

Clearly identify the primary function of the underwater robot. Is it for scientific research, industrial inspection, military use, or environmental monitoring? The intended use will help to dictate the type of robot (ROV or AUV), its capabilities, and the necessary attachments or sensors.

- Operating environment

Consider the environmental conditions where the robot will be deployed. Depth, water currents, visibility, and underwater terrain are critical factors that influence the choice of the robot. Deep-sea exploration requires different capabilities compared to shallow-water or coral reef studies.

Assess technical specifications and capabilities

- Depth capability

Evaluate the maximum depth that your application calls for. ROVs and AUVs have maximum operating depths. Deepwater robots are more robust and equipped to handle high-pressure environments but may be more expensive. Alternatively, robots designed to operate in shallow-water environments will often be more cost and resource-efficient for tasks at those depths.

- Maneuverability and propulsion

Consider the robot's agility and movement capabilities, especially if it needs to navigate complex underwater landscapes or perform precise tasks.

- Sensor and camera quality

High-quality sensors and cameras are crucial for tasks that require detailed data collection and imaging.

- Battery life and power requirements

For AUVs, assess the battery life and range. For ROVs, consider the power supply requirements and how the tether length may impact operations.

Financial considerations

- Budget and cost of ownership

Apart from the initial purchase cost, consider ongoing expenses such as maintenance, repairs, and potential upgrades. Evaluate the total cost of ownership over the robot's expected lifespan.

- Return on investment (ROI)

Consider the potential ROI, especially if the robot is being used for commercial purposes. How will the robot enhance operational efficiency, safety, or data quality, and how does that translate into financial benefits?

Regulatory and compliance issues

- Legal regulations

Be aware of legal and environmental regulations in the areas where the robot will be used. Compliance with maritime and environmental laws is essential.

- Insurance and liability

Consider insurance costs and liability issues, especially for operations in high-risk environments or commercial applications.

Future-proofing and scalability

- Upgrade potential

Check if the robot can be upgraded with new technologies or attachments in the future. Investing in a scalable system can be more cost-effective in the long run.

- Vendor support and warranty

Ensure robust vendor support and check the warranty conditions. Reliable post-sale service and technical support are vital for maintaining the robot's operational efficiency.

In conclusion, investing in an underwater robot is a multifaceted decision that requires a thorough analysis of operational needs, technical specifications, financial considerations, and regulatory compliance. A well-informed decision will ensure that the underwater robot serves the intended purpose effectively and provides a valuable asset to the operation.

Complimentary solutions to underwater robots?

Complementary solutions are often required to maximize the functionality of underwater robots. Operations leaders must determine what additional equipment is needed, such as deployment systems, control units, or data processing software. For ROVs, assess the need for support vessels.

Additionally, investing in training for – or additional – personnel who will operate and maintain the robot is crucial. Ensure you have access to skilled operators or consider the costs of training existing staff.

What skills do you need to operate an underwater robot?

Technical knowledge

Understanding of the robot's systems and functionalities is critical. ROVs and AUVs are highly technical machines. Operators should have technical knowledge of operations, programming, and maintenance to be effective.

Analytical skills

Staff should have the ability to interpret the data collected and make informed decisions. ROVs and AUVs are built for data collection. Downstream data analysis is where much of the value in subsea robots resides.

Problem-solving abilities

Industry veterans know to expect the unexpected when working underwater. Skill in troubleshooting and addressing unexpected challenges during operations is a key component of operating AUVs and ROVs.

What components do underwater robots typically consist of?

The typical primary components of an underwater robot include:

- Propulsion systems: For movement and maneuverability.

- Power supply: Batteries or power from a tether.

- Sensors and cameras: For navigation and data collection.

- Manipulator arms (for some models): To interact with the underwater environment.

What kind of maintenance do they require?

Maintenance of underwater robots involves:

- Regular inspections: Checking for wear and tear, especially after missions.

- Software updates: To ensure optimal performance and security.

- Battery care: Regular charging and, if necessary, replacement.

What’s the expected lifespan of an underwater robot?

The lifespan of an underwater robot depends on several factors, including the frequency of use, maintenance, and operating conditions. On average, a well-maintained underwater robot can last several years, contributing significantly to the sectors it serves. Proper maintenance and operations within the specified design parameters can help extend a subsea robot’s lifespan.

Underwater robots represent a remarkable convergence of technology, innovation, and practical application. As these devices continue to evolve and become more accessible, their impact on various industries and our understanding of the underwater world is poised to grow.

What’s next?

You may be ready to take the next step towards including underwater robots in your subsea operations, but where do you start?

The HowToRobot platform connects buyers of automation with a variety of suppliers in a streamlined, easy-to-use environment.

Post your project on HowToRobot today for free, and begin receiving offers from vetted, relevant automation vendors from our supplier network.

No comments:

Post a Comment