|

| Dual-mode scramjet engine flowfield characteristics |

Revolution at Mach 10: NASA-Backed Hypersonic Jets Poised to Transform Space Travel

Summary

This article discusses recent advancements in hypersonic jet technology for space travel, focusing on research conducted at the University of Virginia with NASA funding. Here are the key points:

1. Researchers are exploring hypersonic jets as a potential alternative to rocket-based space travel, aiming for aircraft-like spacecraft that can take off and land horizontally.

2. The study, published in Aerospace Science and Technology, demonstrates for the first time that airflow in supersonic combusting jet engines (scramjets) can be controlled using an optical sensor.

3. The team achieved adaptive control of a scramjet engine, which is a significant breakthrough for hypersonic propulsion.

4. The research builds on NASA's earlier X-43A and X-51 Waverider projects, which proved the concept of hypersonic flight but lacked reliable engine control.

5. Optical sensors could potentially replace traditional pressure sensors, offering faster response times and more comprehensive data about engine conditions.

6. The team used optical emission spectroscopy to analyze the flame within the engine, providing information about the engine's state that pressure sensors cannot capture.

7. The wind tunnel demonstration showed that engine control can be both predictive and adaptive, smoothly transitioning between scramjet and ramjet functioning.

8. This technology could lead to more efficient, safer, and reusable single-stage-to-orbit aircraft for space travel.

9. While more research is needed, the findings suggest that optical sensors could play a crucial role in controlling future hypersonic vehicles.

10. The ultimate goal is to develop aircraft-like space vehicles that combine cost-efficiency, safety, and reusability, potentially transforming space travel in the coming decades.

Based on the article, here are the researchers involved, their institutions, and related published work:

Researchers and Institution:

1. Christopher Goyne - Professor and Director of the UVA Aerospace Research Laboratory, University of Virginia School of Engineering and Applied Science

2. Chloe Dedic - Associate Professor, University of Virginia School of Engineering and Applied Science

3. Max Chern - Doctoral student, University of Virginia

4. Andrew Wanchek - Former graduate student, University of Virginia

5. Laurie Elkowitz - Doctoral student, University of Virginia

6. Robert Rockwell - Senior scientist, University of Virginia

All researchers are affiliated with the University of Virginia School of Engineering and Applied Science. The main research discussed in this article was published in the journal Aerospace Science and Technology in June 2024. The specific paper is:

Title: "Control of a dual-mode scramjet flow path utilizing optical emission spectroscopy"

Authors: Max Y. Chern, Andrew J. Wanchek, Laurie Elkowitz, Robert D. Rockwell, Chloe E. Dedic and Christopher P. Goyne

Publication Date: 18 April 2024

DOI: 10.1016/j.ast.2024.109144

The article mentions that this work was supported by a NASA ULI (University Leadership Initiative) grant led by Purdue University, suggesting collaboration with other institutions. This article describes an experimental study on controlling the shock train leading edge (STLE) location in a dual-mode scramjet (DMSJ) engine using optical emission spectroscopy (OES) sensors. Here are the key points:

1. The study demonstrates closed-loop control of STLE location using OES sensor feedback for the first time.

2. OES sensors measure light emitted by excited chemical species (OH* and C2*) in the combustor to estimate and control STLE location.

3. The research compares OES sensor feedback to traditional wall pressure sensors for STLE control.

4. Two control methods were tested and compared:

- Proportional-Integral (PI) controller

- Characteristic Model-Based All-Coefficient Adaptive Control (ACAC)

5. Experiments were conducted at the University of Virginia Supersonic Combustion Facility, simulating conditions for a Mach 5 flight vehicle.

6. OES sensors provided smoother response compared to discrete wall pressure measurements.

7. Both PI and ACAC controllers performed similarly under nominal conditions and with introduced plant changes.

8. ACAC tended to command the fuel valve more efficiently than the PI controller.

9. The study demonstrates the potential of using OES sensors for STLE control in scramjet engines, which could improve performance and prevent unstart events.

10. This research contributes to the development of hypersonic propulsion systems for military applications and reusable launch vehicles.

The article emphasizes the novelty of using OES sensors for STLE control and the first experimental demonstration of adaptive control using OES feedback in a scramjet combustor.

Sensor Comparison Metrics

Based on the article, the main metrics used to compare STLE control using OES sensors versus traditional pressure sensors were:

1. Smoothness of response: The article mentions that utilizing an OES sensor for feedback "provided a smoother response than when utilizing discrete wall-based pressure measurements that tended to discretize the estimated STLE location."

2. Bias in STLE location: When using pressure measurements (PRM) for feedback, a bias in STLE location was noticed. The algorithm favored locations near pressure measurements, causing a difference between PRM and OES sensor estimated STLE locations.

3. Controller performance: The study compared how the controllers (PI and ACAC) performed using OES feedback versus pressure sensor feedback. This included looking at their ability to maintain and adjust STLE location according to reference points.

4. Sampling rate: The article notes that one key advantage of OES sensors is "the faster sampling rate that an optical sensor can provide" compared to traditional pressure sensors.

5. Direct measurement: OES sensors were noted to provide "direct measurements of the combustion process itself rather than its effect," which is what pressure sensors measure.

6. Response to plant changes: The study examined how the control systems using different sensors responded to introduced changes, such as mass addition downstream of the combustor and reduced fuel valve response.

7. Fuel valve efficiency: The article mentions that when using OES sensors, the ACAC controller "tended to command the fuel valve more efficiently" compared to the PI controller.

While the article doesn't provide specific quantitative metrics, these qualitative comparisons were used to evaluate the performance of OES sensors against traditional pressure sensors for STLE control.

Control Algorithm Comparison

Based on the information provided in the article, the comparison between the Proportional-Integral (PI) and Characteristic Model-Based All-Coefficient Adaptive Control (ACAC) controllers was primarily qualitative. However, we can infer some metrics that were likely used to compare their performance:

1. Response to nominal operation: The article states that "ACAC and PI controllers behave similarly both during nominal operation."

2. Response to plant changes: The controllers were compared when changes were introduced, such as "mass addition downstream of the combustor and a reduction of fuel valve response."

3. Fuel valve efficiency: The article mentions that "the ACAC controller tended to command the fuel valve more efficiently."

4. Ability to maintain/track STLE location: This was likely assessed based on how well each controller maintained the desired STLE location during different duty cycles.

5. Stability during transient processes: While not explicitly compared, this was mentioned as an advantage of the ACAC controller.

The article doesn't provide specific scoring methods for these metrics. The comparison appears to be based on observational analysis rather than a formal scoring system. The researchers likely used their "expert judgment" to assess the relative performance of the controllers based on these criteria.

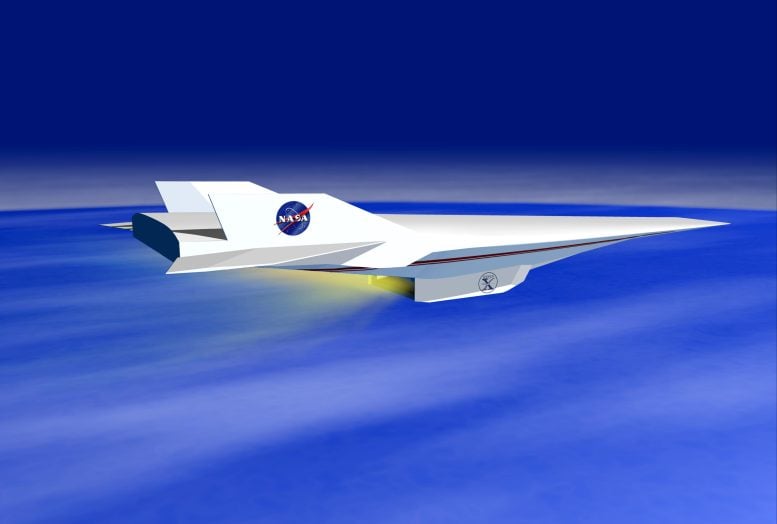

This is an artist’s depiction of a Hyper-X research vehicle under scramjet power in free-flight following separation from its booster rocket. New research into hypersonic jets may transform space travel by making scramjet engines more reliable and efficient, leading to aircraft-like spacecraft. Credit: NASA

Wind Tunnel Study Reveals Hypersonic Jet Engine Flow Can Be Controlled Optically

Researchers at the University of Virginia are exploring the potential of hypersonic jets for space travel, using innovations in engine control and sensing techniques. The work, supported by NASA, aims to enhance scramjet performance through adaptive control systems and optical sensors, potentially leading to safer, more efficient space access vehicles that function like aircraft.

The Future of Space Travel: Hypersonic Jets

What if the future of space travel were to look less like Space-X’s rocket-based Starship and more like NASA’s “Hyper-X,” the hypersonic jet plane that, 20 years ago this year, flew faster than any other aircraft before or since?

In 2004, NASA’s final X-43A unmanned prototype tests were a milestone in the latest era of jet development — the leap from ramjets to faster, more efficient scramjets. The last test, in November of that year, clocked a world-record speed only a rocket could have achieved previously: Mach 10. The speed equates to 10 times the speed of sound.

NASA culled a lot of useful data from the tests, as did the Air Force six years later in similar tests on the X-51 Waverider, before the prototypes careened into the ocean.

Although hypersonic proof of concept was successful, the technology was far from operational. The challenge was achieving engine control, because the tech was based on decades-old sensor approaches.

NASA’s B-52B launch aircraft cruises to a test range over the Pacific Ocean carrying the third and final X-43A vehicle, attached to a Pegasus rocket, on November 16, 2004. Credit: NASA / Carla Thomas

Breakthroughs in Hypersonic Engine Control

This month, however, brought some hope for potential successors to the X-plane series.

As part of a new NASA-funded study, University of Virginia School of Engineering and Applied Science researchers published data in the June issue of the journal Aerospace Science and Technology that showed for the first time that airflow in supersonic combusting jet engines can be controlled by an optical sensor. The finding could lead to more efficient stabilization of hypersonic jet aircraft.

In addition, the researchers achieved adaptive control of a scramjet engine, representing another first for hypersonic propulsion. Adaptive engine control systems respond to changes in dynamics to keep the system’s overall performance optimal.

“One of our national aerospace priorities since the 1960s has been to build single-stage-to-orbit aircraft that fly into space from horizontal takeoff like a traditional aircraft and land on the ground like a traditional aircraft,” said professor Christopher Goyne, director of the UVA Aerospace Research Laboratory, where the research took place.

“Currently, the most state-of-the-art craft is the SpaceX Starship. It has two stages, with vertical launch and landing. But to optimize safety, convenience, and reusability, the aerospace community would like to build something more like a 737.”

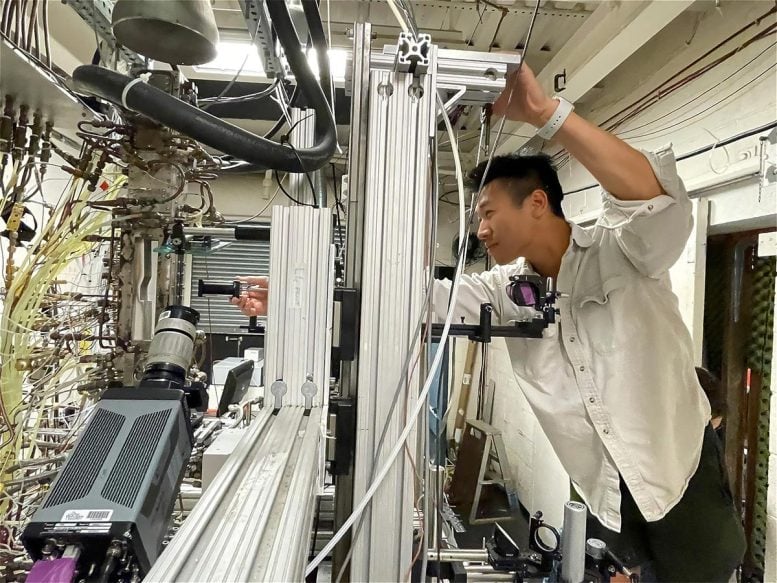

Doctoral student Max Chern takes a closer look at the wind tunnel setup where University of Virginia School of Engineering and Applied Science researchers demonstrated that control of a dual-mode scramjet engine is possible with an optical sensor. Credit: Wende Whitman, UVA Engineering

Goyne and his co-investigator, Chloe Dedic, a UVA Engineering associate professor, believe optical sensors could be a big part of the control equation.

“It seemed logical to us that if an aircraft operates at hypersonic speeds of Mach 5 and higher, that it might be preferable to embed sensors that work closer to the speed of light than the speed of sound,” Goyne said.

Additional members of the team were doctoral student Max Chern, who served as the paper’s first author, as well as former graduate student Andrew Wanchek, doctoral student Laurie Elkowitz and UVA senior scientist Robert Rockwell. The work was supported by a NASA ULI grant led by Purdue University.

Enhancing Scramjet Engine Performance

NASA has long sought to prevent something that can occur in scramjet engines called “unstart.” The term indicates a sudden change in airflow. The name derives from a specialized testing facility called a supersonic wind tunnel, where a “start” means the wind has reached the desired supersonic conditions.

UVA has several supersonic wind tunnels, including the UVA Supersonic Combustion Facility, which can simulate engine conditions for a hypersonic vehicle traveling at five times the speed of sound.

“We can run test conditions for hours, allowing us to experiment with new flow sensors and control approaches on a realistic engine geometry,” Dedic said.

Goyne explained that “scramjets,” short for supersonic combustion ramjets, build on ramjet technology that has been in common use for years.

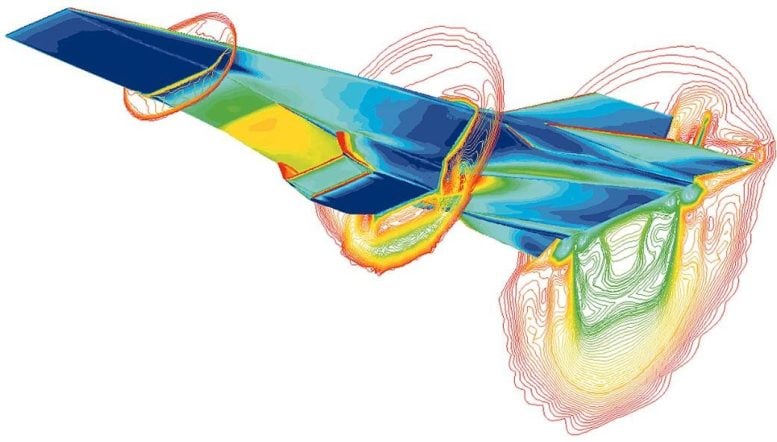

This computational fluid dynamics image from the original Hyper-X tests shows the engine operating at Mach 7. Credit: NASA

Ramjets essentially “ram” air into the engine using the forward motion of the aircraft to generate the temperatures and pressures needed to burn fuel. They operate in a range of about Mach 3 to Mach 6. As the inlet at the front of the craft narrows, the internal air velocity slows down to subsonic speeds in a ramjet combustion engine. The plane itself, however, does not.

Scramjets are a little different, though. While they are also “air-breathing” and have the same basic setup, they need to maintain that super-fast airflow through the engine to reach hypersonic speeds.

“If something happens within the hypersonic engine, and subsonic conditions are suddenly created, it’s an unstart,” Goyne said. “Thrust will suddenly decrease, and it may be difficult at that point to restart the inlet.”

Testing a Dual-Mode Scramjet Engine

Currently, like ramjets, scramjet engines need a step-up to get them to a speed where they can intake enough oxygen to operate. That may include a ride attached to the underside of a carrier aircraft as well as a rocket boost.

The latest innovation is a dual-mode scramjet combustor, which was the type of engine the UVA-led project tested. The dual engine starts in ramjet mode at lower Mach numbers, then shifts into receiving full supersonic airflow in the combustion chamber at speeds exceeding Mach 5.

Preventing unstart as the engine makes that transition is crucial.

Christopher Goyne, professor and director of the UVA Aerospace Research Laboratory, and Chloe Dedic, associate professor. Credit: Wende Whitman, UVA Engineering

Incoming wind interacts with the inlet walls in the form of a series of shock waves known as a “shock train.” Traditionally, the leading edge of those waves, which can be destructive to the aircraft’s integrity, have been controlled by pressure sensors. The machine can adjust, for example, by relocating the position of the shock train.

But where the leading edge of the shock train resides can change quickly if flight disturbances alter mid-air dynamics. The shock train can pressurize the inlet, creating the conditions for unstart.

So, “If you are sensing at the speed of sound, yet the engine processes are moving faster than the speed of sound, you don’t have very much response time,” Goyne said.

He and his collaborators wondered if a pending unstart could be predicted by observing properties of the engine’s flame instead.

Sensing the Spectrum of a Flame

The team decided to use an optical emission spectroscopy sensor for the feedback needed to control the shock train leading edge.

No longer limited to information obtained at the engine’s walls, as pressure sensors are, the optical sensor can identify subtle changes both inside the engine and within the flow path. The tool analyzes the amount of light emitted by a source — in this case, the reacting gases within the scramjet combustor — as well as other factors, such as the flame’s location and spectral content.

“The light emitted by the flame within the engine is due to relaxation of molecular species that are excited during combustion processes,” explained Elkowitz, one of the doctoral students. “Different species emit light at different energies, or colors, offering new information about the engine’s state that is not captured by pressure sensors.”

Current UVA Engineering mechanical and aerospace doctoral students Laurie Elkowitz and Max Chern were among the influential members of the team. Credit: Wende Whitman, UVA Engineering

The team’s wind tunnel demonstration showed that the engine control can be both predictive and adaptive, smoothly transitioning between scramjet and ramjet functioning.

The wind tunnel test, in fact, was the world’s first proof that adaptive control in these types of dual-function engines can be achieved with optical sensors.

“We were very excited to demonstrate the role optical sensors may play in the control of future hypersonic vehicles,” first author Chern said. “We are continuing to test sensor configurations as we work toward a prototype that optimizes package volume and weight for flight environments.”

Building Toward the Future

While much more work remains to be done, optical sensors may be a component of the future Goyne believes will be realized in his lifetime: plane-like travel to space and back.

Dual-mode scramjets would still require a boost of some sort to get the aircraft to at least Mach 4. But there would be the additional safety of not relying exclusively on rocket technology, which requires highly flammable fuel to be carried alongside large amounts of chemical oxidizer to combust the fuel.

That decreased weight would allow more room for passengers and payload.

Such an all-in-one aircraft, which would glide back to Earth like the space shuttles once did, might even provide the ideal combination of cost-efficiency, safety and reusability.

“I think it’s possible, yeah,” Goyne said. “While the commercial space industry has been able to lower costs through some reusability, they haven’t yet captured the aircraft-like operations. Our findings could potentially build on the storied history of Hyper-X and make its space access safer than current rocket-based technology.”

Reference: “Control of a dual-mode

scramjet flow path utilizing optical emission spectroscopy” by Max Y.

Chern, Andrew J. Wanchek, Laurie Elkowitz, Robert D. Rockwell, Chloe E.

Dedic and Christopher P. Goyne, 18 April 2024, Aerospace Science and Technology.

DOI: 10.1016/j.ast.2024.109144

Control of a dual-mode scramjet flow path utilizing optical emission spectroscopy

Get rights and content

Abstract

Shock train leading edge (STLE) location control within a Dual-Mode Scramjet (DMSJ) flow path was demonstrated using an optical emission spectroscopy (OES) sensor for control feedback. Emission from electronically excited chemical species, OH⁎ and C, was observed within the combustor and used for feedback to control the STLE within the DMSJ isolator. An optical emission sensor was used to experimentally demonstrate STLE control using a Proportional-Integral (PI) controller. Feedback using this sensor was compared the traditional approach of using wall pressure sensors. Utilizing an OES sensor for feedback proved to be an effective method to estimate and control the STLE location and provided a smoother response than when utilizing discrete wall-based pressure measurements that tended to discretize the estimated STLE location. Characteristic Model-Based All-Coefficient Adaptive Control (ACAC) was also implemented and compared to the PI controller response using the OES signal as feedback. Plant changes were introduced in the form of mass addition downstream of the combustor and a reduction of fuel valve response. Experiments showed that the ACAC and PI controllers behave similarly both during nominal operation and with plant changes, though the ACAC controller tended to command the fuel valve more efficiently. This paper presents the first experimental demonstration of closed-loop control of the STLE location within a scramjet flow path when using OES sensor feedback. This is also the first demonstration of adaptive control of STLE location utilizing OES sensor feedback.

Access through your organization

Check access to the full text by signing in through your organization.

Introduction

Scramjet technology has the potential to propel hypersonic military systems and reusable launch vehicles for responsive space access. Concepts such as the NASA X-43A have been developed to demonstrate the practical use of scramjets [1], [2]. A special type of scramjet, known as a dual-mode scramjet (DMSJ), makes ample use of an isolator upstream of the combustor. The isolator reduces the incoming flow to subsonic conditions via a shock train. This extends the operational range of the engine by allowing it to operate in a ramjet mode. Therefore, between about Mach 3 and 6, a DMSJ typically operates with a precombustion shock train in the isolator and with subsonic fuel-air mixing and combustion in the combustor [3].

The isolator shock train works to match the scramjet inlet pressure with the higher downstream combustor pressure. The location of the shock train leading edge (STLE) is indicative of engine conditions and is sensitive to inlet, and combustor conditions [4]. As the combustor pressure increases relative to the inlet pressure, the shock train increases in length. The STLE can travel forward into the scramjet inlet, causing subsonic flow in the inlet, during an event called unstart. Unstart is detrimental to a flight vehicle as it greatly reduces mass flow into the engine, which in turn, reduces thrust and increases drag [5]. Unstart prevention is required for hypersonic air-breathing engines as an unexpected unstart event could lead to the loss of the vehicle. A common, passive method to reduce the risk of unstart is to increase the length of the isolator, but this also increases the overall engine length and weight. Alternatively, active control of the STLE offers another approach for maximizing the operational envelope and the performance of the engine.

Many different active control methods for preventing unstart have been proposed including boundary layer suction [6], mass addition via vortex generator jets [7], plasma actuation [8], back pressure regulation via ramp actuation downstream of the combustor [9], [10], and active fueling control [11], [12], [13], [14]. An advantage to using active fueling control for unstart prevention is that it can largely use the existing fuel system, reducing complexity of the hardware design and fabrication. Controlling fuel as a method of controlling STLE location is possible because of the pressure balance taking place within the engine. As the fueling rate increases, increased heat release in the combustor leads to an increase in combustor pressure, which moves the STLE forward in the isolator. The opposite occurs when the fueling rate is decreased. Coupling of the combustion reaction with the overall engine state and STLE location enables the utilization of combustor sensors as feedback for STLE estimation and control.

Pressure sensors are typically used to measure combustor state, but recent studies have shown benefits of using optical sensors [14], [15]. Optical emission spectroscopy (OES) provides a spectrally-resolved measurement of the light emitted following the formation of electronically-excited species in a chemical reaction. During ethylene combustion, or any hydrocarbon combustion process, electronically excited OH⁎, CH⁎ and C are formed as intermediate species [16]. The relative intensities of light emitted from these species have been shown to be correlated with local fueling equivalence ratio (ER) in partially premixed flames [17]. Such an established correlation can be used to control ER or STLE location in a scramjet, through closed-loop control approaches. Fig. 1 visualizes how OES measurements may be used to control the STLE in a scramjet in such a control loop. It depicts two different measured emission spectra that correspond to two different STLE locations, at a different equivalence ratios in the scramjet combustor. As the ER increases, the spectra measured from the flame chemiluminescence changes. This corresponds to a change in shock train length and STLE location. The key advantages of using OES for sensing of engine parameters is the ability to obtain direct measurements of the combustion process itself rather than its effect, i.e. isolator pressure rise, as well as the faster sampling rate that an optical sensor can provide. Previous work has applied this concept to DMSJ control by using the ratio of integrated C and OH⁎ emission intensities to control fuel pressure and, hence, combustor global ER [14]. Although Refs. [14] and [15] establish a link between the OES signal at a specific location and global ER, and STLE control using OES has been proposed in previous work. [18], the concept has not yet been experimentally demonstrated.

If inlet conditions of a scramjet remain constant, a correlation between the combustor state, as estimated by an OES sensor, and STLE location may be established. However, this is not always the case during flight. Many factors can cause inlet conditions to change during flight, such as changes in altitude, weather [19], and Angle-of-Attack (AoA) of the vehicle [20], [21]. These factors will cause the STLE behavior to deviate from the baseline condition and may lead to unfavorable controller responses. Other changes, such as hardware malfunctions (i.e. a reduction in valve response), engine geometry change due to thermal expansion, or changes in the optical transmission of windows will likewise cause a change in the plant of the control system. Ultimately, an engine control system on a flight vehicle may use multiple sensor types for feedback. The goal of this work is to demonstrate that the relationship between OES sensor measurements and STLE location is sufficient for closed loop control of the STLE and to explore the advantages of using OES sensors over traditional pressure measurement.

An adaptive controller may be required to mitigate issues that arise from uncertainties in scramjet operability and performance of a real flight system. Therefore, a Model Reference Adaptive Controller (MRAC) was examined in this study; an approach called “Characteristic Model-Based All-Coefficient Adaptive Control (ACAC).” [22] MRAC is typically deployed on plants where uncertainties can be in the form of degradation, uncertain plant dynamics, or other unmodeled phenomenon [23]. Direct MRAC utilizes adaptive parameters to adjust controller gains and provide a defined system performance, whereas indirect MRAC utilizes adaptive parameters to model the system dynamics, and are used directly in the control law. The form of MRAC used in this work, ACAC, is an indirect method developed by Wu and Xie [24] and has been applied to many engineering plants [22], including the control of a high-speed rotor supported on magnetic bearings [25] and simulated altitude control for the X-34 launch vehicle [26]. ACAC was selected for use in the current study due to its relatively simple implementation and its stability during transient processes [24]. ACAC utilizes a plant estimation method known as characteristic modeling to provide a real-time estimation of the plant response. This estimation is then implemented directly into the golden section adaptive control law to provide a robustly stable system, even during transient processes [24].

Other control laws can be implemented to aid in the performance of the ACAC controller while taking advantage of its stability properties. Maintaining/tracking, derivative, and integral control laws have been employed with ACAC to provide good closed-loop performance for engineering systems [22]. Although ACAC has been around since the 1990's, there is little experimental results published using the controller. This study provides an experimental analysis of this controller when compared to the more standard proportional-integral (PI) controller. Due to the uncertain and non-linear nature of DMSJ operation and link to combustor emission, ACAC is a good candidate for the control of the DMSJ flowpath using the OES sensors as feedback due to its adaptive qualities.

This study builds on the work of Ref. [18] where the possibility of utilizing OES for STLE control was explored through simulation. The present study has two objectives: (1) demonstrate experimental closed-loop control of the STLE location in a scramjet isolator flow path utilizing OES feedback, and (2) explore adaptive control in comparison to a standard PI control method for this system. This is the first demonstration of closed-loop control of the STLE location within a scramjet isolator flow path utilizing OES sensor feedback. This is also the first time adaptive control was experimentally demonstrated utilizing OES sensor feedback from a scramjet combustor.

In this paper, the experimental facility setup is described in two parts: subsection 2.1 provides details of the facility conditions, instrumentation, actuators, and control hardware, and subsection 2.2 provides details on the method of optical emission sensing and its synchronization with the control system. The control setup is then described in four parts: subsection 3.1 explains the method by which pressure measurements within the isolator were used to estimate the STLE, subsection 3.2 explains how these estimations were used in conjunction with OES measurements to provide calibrations for the control loop, subsection 3.3 explains the closed loop control loop that was implemented, and finally, subsection 3.4 explains the control law of the ACAC controller. The results and discussion section begins with a brief outline of the test conditions and duty cycles that were examined and then the results are examined in two parts: subsection 4.1, which discusses the performance of the controller using OES feedback in comparison to pressure sensors, and subsection 4.2, which discusses the performance of the ACAC controller. Finally, a conclusion summarizes the results and impacts of this work.

Section snippets

Facility and instrumentation

The experiments in this paper were conducted at the University of Virginia Supersonic Combustion Facility (UVASCF). The facility consists of an electrically heated, continuous-flow, direct-connect wind tunnel which was used to provide air at 1200 K and 300 kPa total conditions to a DMSJ flow path through a Mach 2 nozzle. This condition simulates the engine inflow Mach number and enthalpy of a flight vehicle at approximately Mach 5 [27], [28]. The facility conditions are measured and recorded on

Control setup

This section details the methods by which closed loop STLE control was achieved. This begins with a description of how the STLE was detected, followed by the method by which the OES signal was calibrated to the STLE. Details are then provided on how the control loop was implemented, followed by the control law of the ACAC controller.

Results and discussion

In order to fully examine control effectiveness, two duty cycles with step changes of reference STLE location was exercised with each controller: the “Constant Step Size” duty cycle with steps of ±5 x/H between -20 and -35 x/H, and the “Differing Step Size” duty cycle with steps of different sizes between -20 and -35 x/H. The time between the step changes was 3 seconds to allow the STLE location to stabilize at each location. Each duty cycle was repeated at least twice for each controller at

Conclusion

The control of the STLE location using OES sensor feedback was experimentally demonstrated and was shown to be a viable approach. Utilizing the OES sensor as feedback provided a comparable response to using the PRM as feedback. Bias in STLE location was noticed during control with the PRM, though, as the algorithm favored locations near pressure measurements. This bias caused a difference between PRM and OES sensor estimated STLE location. Introducing flow imaging of the isolator flow path was

CRediT authorship contribution statement

Max Y. Chern: Data curation, Investigation, Writing – original draft, Writing – review & editing. Andrew J. Wanchek: Writing – original draft, Software, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. Laurie Elkowitz: Methodology, Formal analysis, Data curation, Validation, Writing – original draft. Robert D. Rockwell: Data curation, Investigation, Supervision, Validation. Chloe E. Dedic: Methodology, Investigation, Funding acquisition, Conceptualization, Project

Declaration of Competing Interest

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests: Andrew Wanchek reports financial support was provided by NASA Aeronautics Research Mission Directorate. Max Chern reports financial support was provided by NASA Aeronautics Research Mission Directorate. Laurie Elkowitz reports financial support was provided by National Defense Science and Engineering Graduate Fellowship. If there are other authors, they declare

Acknowledgements

The authors would like to thank Jack Donnellan and Joe Fritch from GE Aerospace for their support. This work was financially supported by NASA's Space Technology Research Grants Program (NASA ULI Grant #80NSSC21M0069 P00001). L. Elkowitz was supported by the National Defense Science and Engineering Graduate (NDSEG) Fellowship.

References (35)

- et al.

Mechanisms of C2* and CH* formation in a hydrogen-oxygen flame containing hydrocarbon traces

Symp. (Int.) Combust.

(1971)

- N. Li

Response of shock train to fluctuating angle of attack in a scramjet inlet-isolator

Acta Astronaut.

(2022)

- K. Xu et al.

Mechanism of shock train rapid motion induced by variation of attack angle

Acta Astronaut.

(2017)

- L. Marshall et al.

A chief engineer's view of the NASA X-43A scramjet flight test

- T.P. Jones et al.

Evaluation of the X-43A scramjet engine controller performance by Monte Carlo technique

- C. Segal

The Scramjet Engine: Processes and Characteristics

(2011)

- D.B. Le et al.

Shock train leading-edge detection in a dual-mode scramjet

(2008)

- J.L. Wagner et al.

Experimental investigation of unstart in an inlet/isolator model in Mach 5 flow

AIAA J.

(2009)

- K. Kang et al.

Fast-acting boundary-layer suction control of unstarting flows in an ethylene-fueled dual-mode scramjet

AIAA J.

(2021)

- A. Valdivia et al.

Active control of supersonic inlet unstart using vortex generator jets

The manipulation of an unstarting supersonic flow by plasma actuator

J. Phys. D, Appl. Phys.

(2012)

Closed-loop control of unstart in a Mach 1.8 isolator

(2020)

Scramjet Isolator Modeling and Control Dissertation

(2011)

Simulated shock train control using an all-coefficient adaptive control approach

Shock train position control in an axisymmetric scramjet combustor flowpath

Retrospective cost adaptive control of unstart in a model scramjet combustor

AIAA J.

(2018)

Dual-mode scramjet control using optical emission sensors

Appl. Opt.

(2024)

Cited by (0)

- 1

Department of Mechanical and Aerospace Engineering.

© 2024 Elsevier Masson SAS. All rights reserved.

No comments:

Post a Comment